Coolers, also known as rotary drum coolers, are used in compound fertilizer production to cool fertilizers of a certain temperature and particle size. Used in conjunction with dryers, they significantly increase cooling speed, reduce labor intensity, and increase yield. They further remove moisture and lower the particle temperature of compound fertilizers. They can also be used to cool other powdered and granular materials. Coolers offer a compact structure, high cooling efficiency, reliable performance, and strong adaptability.

1. Beautiful appearance, simple operation, low energy consumption, longlife, uniform cooling, and easy maintenance.

2. Low investment, quick results, good economic benefits, reliable performance, and can be used for cooling powdered and granular materials.

3. Small power, no three wastes, stable operation, convenient maintenance, reasonable process layout, advanced technology, and low production cost.

4. The distribution and angle design of the lifting plate are beautiful, and the performance is reliable, so the wind energy utilization rate is high, the cooling is uniform, and the number of material cleaning times is small.

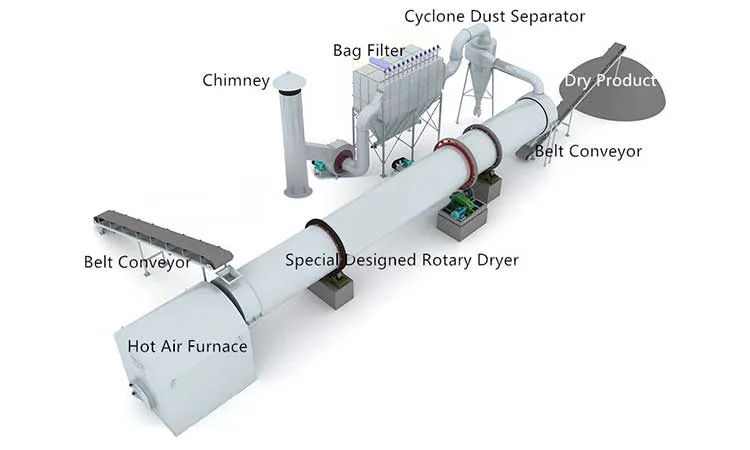

The dried wet material is transported to the hopper by a belt conveyor or bucket elevator. It then enters the feeder through the feed pipe and into the feed end. The feed pipe's slope should be greater than the material's naturalinclination to ensure smooth material flow into the cooler. The cooler cylinder is a rotating cylinder slightly inclined to the horizontal. Material is fed in at the higher end, while the heat carrier exits at the lower end, interactingwith the material in countercurrent flow. Sometimes, the heat carrier and material enter the cylinder together. As the cylinder rotates, the material flows by gravity to the lower end. As the wet material moves forward within the tube, it receives heat directly or indirectly from the heat carrier, cooling it. It is then discharged at the discharge end via a belt conveyor or screw conveyor. A lifting plate is installed on the inner wall of the cylinder to liftand lower the material, increasing its contact surface with the airflow, thereby increasing the cooling rate and promoting material forward movement. The cooling medium is generally composed of cold air and other media. After the heat carrierpasses through the cooler, a cyclone dust collector is typically required to capture any material carried in the air. If you need to further reduce the dust content in the exhaust gas, it should also pass through a bag filter or wet dust collector before discharging.

| Spec. (Dia.x Length mm) | Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air Temperature(℃) | Rotate Speed(r/min) | Main Motor(kw) |

| Φ600x6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800x8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800x10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000x10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000x12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200x8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800x12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000x18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000x20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400x16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400x18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400x20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600x24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600x28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000x20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 85 |

| Φ3000x25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3200x25000 | 201 | 42.9-53.6 | 3~5 | 700~800 | 1.5~5 | 110 |

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap