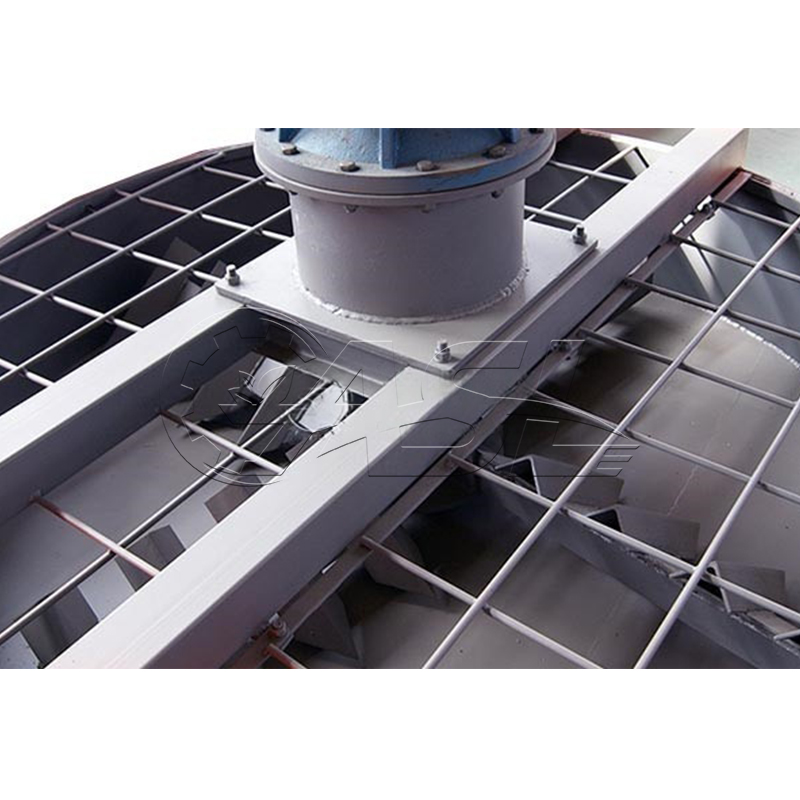

Disc mixer

It can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries.

It can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries.

The pan mixer is a new type of equipment, improved upon the existing mixer. The motor drives the reducer, which in turn drives the main shaft, which in turn drives the stirring teeth to agitate the material. This ensures thorough mixing, improving mixing uniformity. The novel rotor structure allows the minimum clearance between the rotor and the housing to be adjusted to near zero, effectively reducing residual material. The pan is lined with polypropylene or stainless steel, making it less prone to sticking and more wear-resistant. The cycloidal pinwheel reducer provides a compact structure, easy operation, uniform mixing, and convenient unloading and conveying. The overall structure is more rational, the appearance is attractive, and operation and maintenance are easy.

1. High mixing efficiency and a compact footprint. The spiral blades are made of a highly wear-resistant special alloy.

2. The cycloidal pinwheel reducer provides a compact structure, uniform mixing, convenient unloading and conveying, smooth rotation, and low noise.

3. The pan mixer features a top feed and bottom discharge configuration.

4. Tight seals between all joints ensure stable operation.

1. Frame part: All working parts of the organic fertilizer vertical disc mixer are installed and fixed on the frame. The frame of the machine is welded with high-quality carbon steel plates and channel steels, and has passed strict

product certification and specific process requirements, and has achieved the purpose of the machine;

2. Transmission connection part: The organic fertilizer vertical disc mixer uses a cycloidal pinwheel reducer to drive the main shaft to rotate, and its main working part uses nylon pins as transmission connectors to transmit drive,

which is convenient for assembly and maintenance;

3. Mixing working part: The transmission wheel transmits to the main shaft through the pin coupling. The organic fertilizer vertical disc mixer evenly turns the material in the mixing chamber, so that the material can be fully

combined, thereby greatly reducing the residual amount of the material.

Model | Capacity(t/h) | Power(kw) | Dimensions of the shape(mm) |

1600 | 2-4 | 7.5 | 1600×1600×1800 |

1800 | 3-5 | 7.5 | 1800×1800×1800 |

2000 | 4-6 | 7.5 | 2000×2000×1800 |

2200 | 6-8 | 7.5 | 2200×2200×1850 |

3000 | 8-12 | 15 | 3000×3000×2000 |

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap