Shaft Horizontal Mixer

Refractory materials, power plants, metallurgy, chemical industry, organic fertilizer production and other industries.

Refractory materials, power plants, metallurgy, chemical industry, organic fertilizer production and other industries.

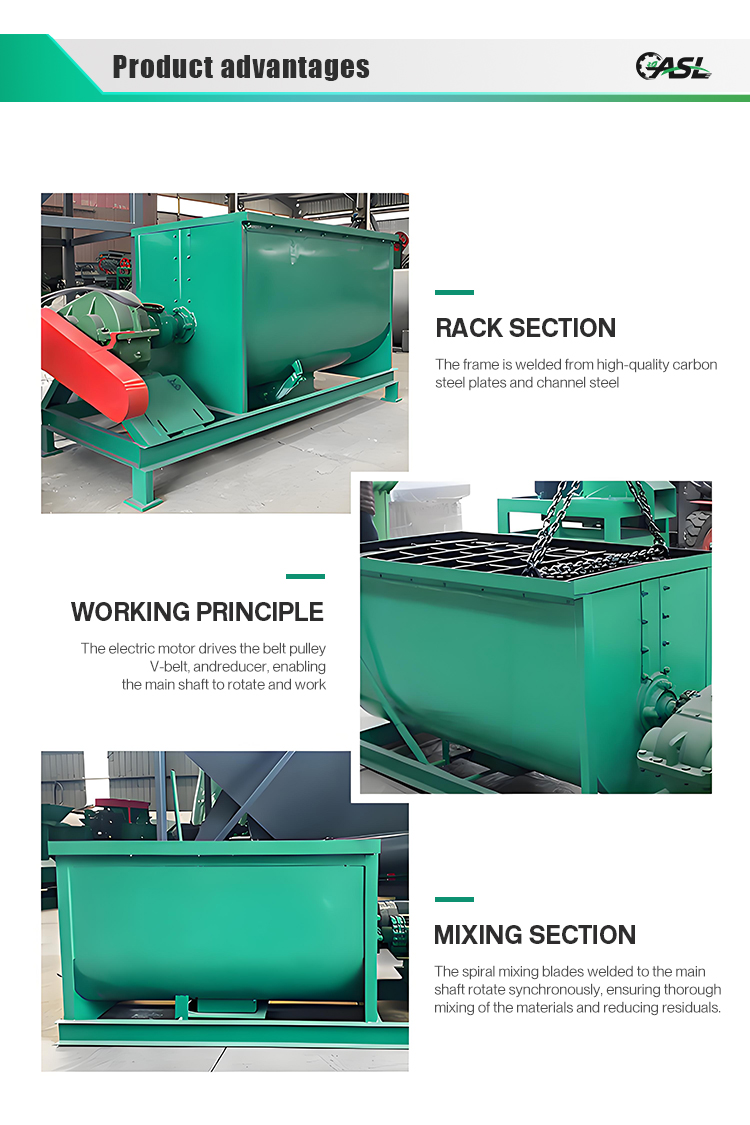

The double-shaft horizontal mixer is used to evenly mix fly ash and other raw materials with aggregates, additives, etc. The double-shaft mixing humidifier is a standardized series product of our company. It has absorbed the advantages of similar products at home and abroad, and has been proved by users for a long time that its various indicators have met the use requirements.

1. The mixer blades made of highly wear-resistant materials are a reliable guarantee for the long service life and normal operation of the mixer.

2. The rationally designed shaft seat and sealing device structure are not only convenient for maintenance, but also completely eliminate the leakage and bubbling of water.

3. The pre-watering section is added to make the mixing effect better. The spacious flip inspection door makes the maintenance work comfortable and easy.

4. The flexible and reliable electrical control system makes the operation safe and simple.

The double-shaft horizontal mixer includes first and second stirring shafts parallel to each other, stirring blades and a horizontal stirring barrel, wherein the stirring blades extend from the first and second stirring shafts in

all directions, and are arranged in equidistant order in the axial direction and differ from each other by a fixed angle in the clockwise or counterclockwise direction in the circumferential direction, so that the stirring blades on the

first and second stirring shafts form a spiral arrangement with opposite rotation directions; the first and second stirring shafts rotate synchronously with each other and their blades staggeredly pass through the plane determined

by the axes of the first and second stirring shafts; a feed port is provided at the top of one end of the stirring barrel, and a discharge port is provided at the bottom of the other end of the stirring barrel. With this structure, the

stirring blades of the mixer discharge the dry mortar from the feed port to the feed port while stirring the dry mortar, thereby achieving continuous production and effectively improving production efficiency.

Model | Capacity(t/h) | Spindle speed(Y/mm) | Rotational diameter(mm) |

400 | 20 | 52 | 400 |

450 | 25 | 52 | 450 |

500 | 30 | 53 | 500 |

550 | 35 | 53 | 550 |

600 | 40 | 54 | 600 |

650 | 45 | 54 | 650 |

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap