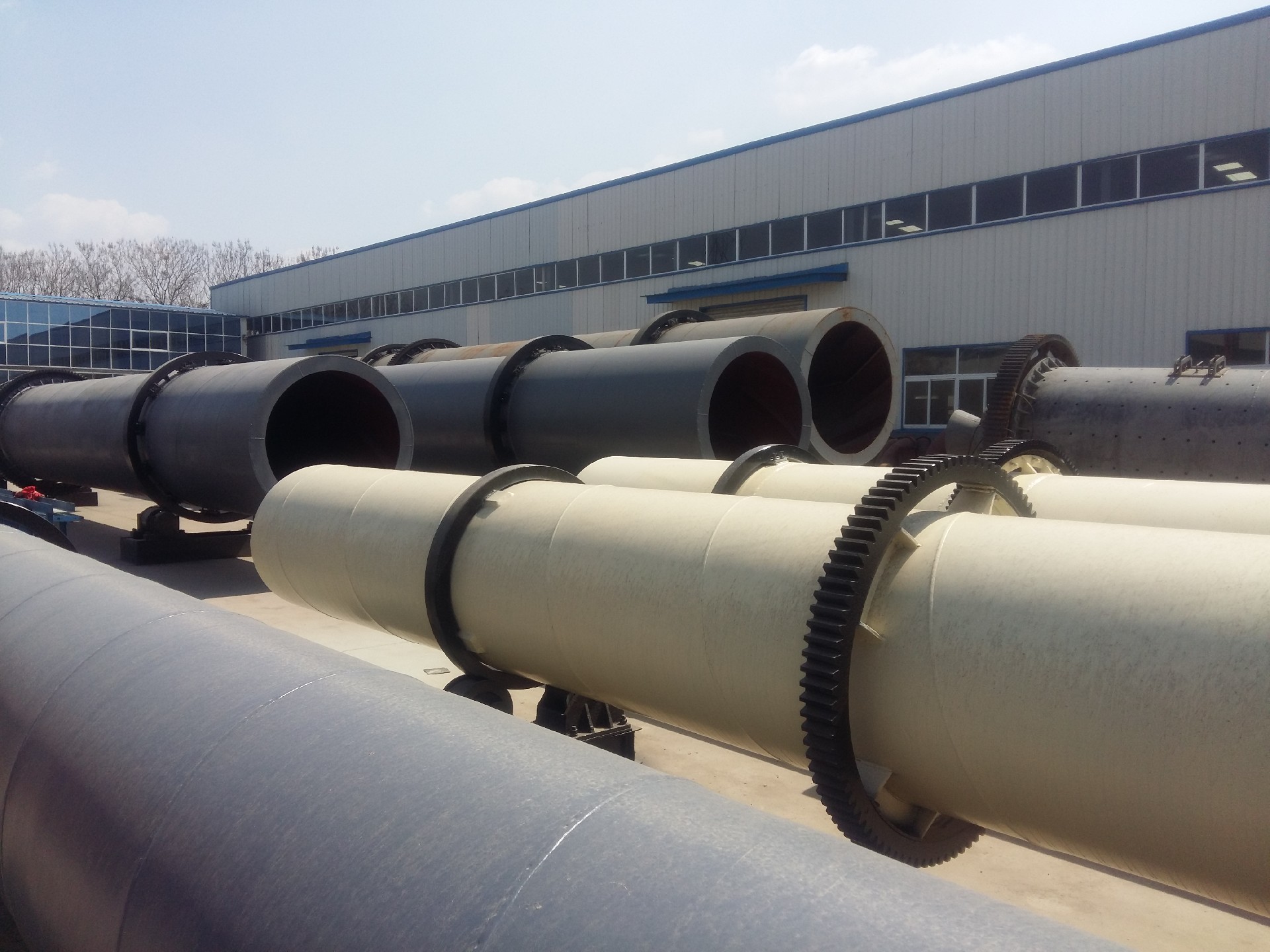

Chicken manure dryer

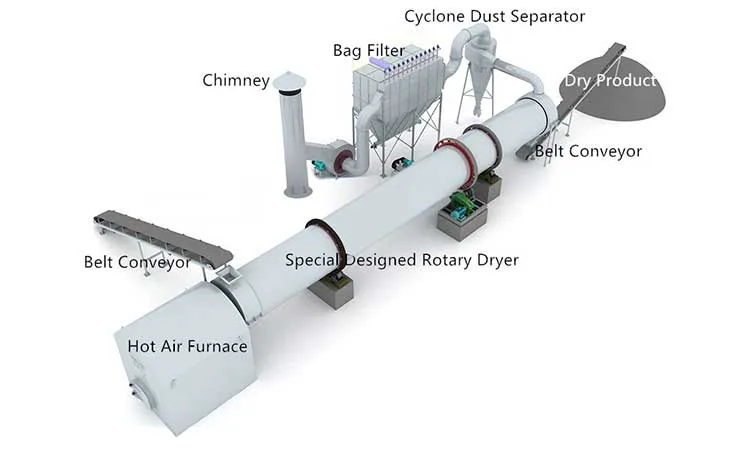

The rotary dryer is a large machine used to dry shaped fertilizer particles. It is one of the key equipment in the fertilizer industry. The machine uses a fan installed at the tail of the machine to continuously draw the heat from the hot air furnace at the head of the machine to the tail

Product Description

The rotary dryer is a large machine used to dry shaped fertilizer

particles. It is one of the key equipment in the fertilizer industry. The

machine uses a fan installed at the tail of the machine to continuously draw the

heat from the hot air furnace at the head of the machine to the tail of the

machine. As the machine rotates continuously, the lifting plate inside it

continuously lifts and drops the shaped particles, so that the material is fully

in contact with the hot air to take away the moisture in it, thereby achieving

the drying effect. Livestock manure dryer, livestock manure dryer price,

livestock manure dryer manufacturer.

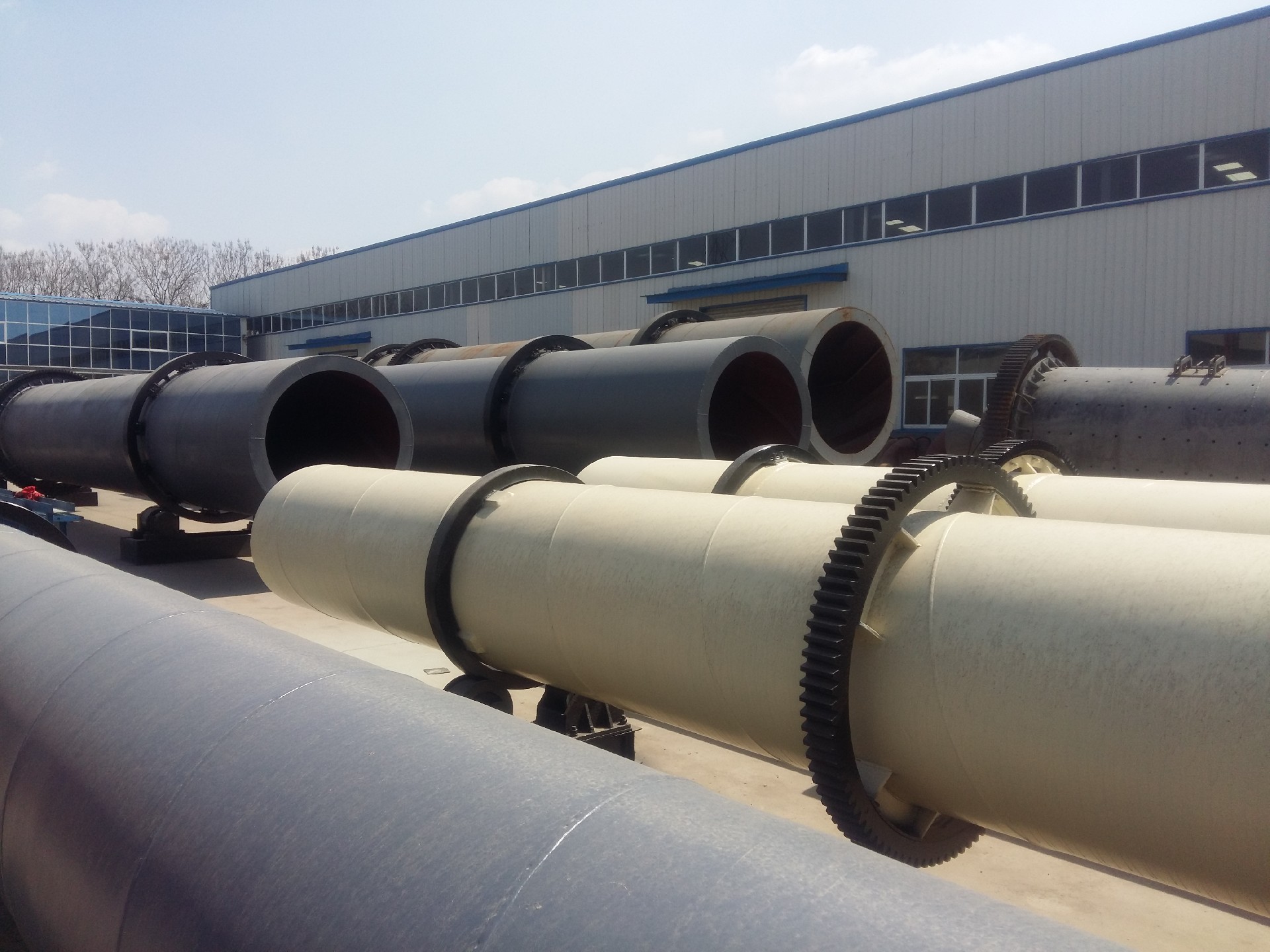

Product Features

Large processing capacity, low fuel consumption and low drying cost. The dryer is resistant to high temperatures and can use high-temperature hot air to quickly dry materials. It has strong scalability and the design takes production margin into consideration. Even if the output increases slightly, there is no need to replace the equipment. The equipment adopts a self-aligning tugboat structure, and the tugboat and roller are well matched, which greatly reduces wear and power consumption. The specially designed wheel structure greatly reduces the horizontal thrust caused by the tilting operation of the equipment. It has strong overload resistance, stable cylinder operation and high reliability. Poultry and livestock manure dryer, poultry and livestock manure dryer price, poultry and livestock manure dryer manufacturer

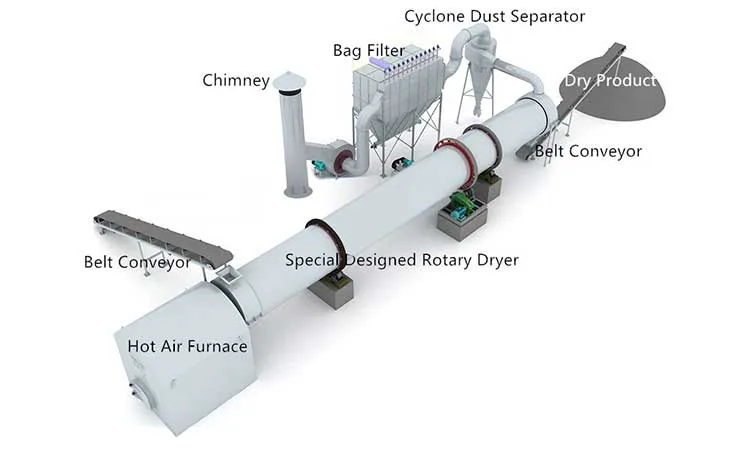

Working Principle

The dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe storage moisture content of 13% at one time. The entire process is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of a heat source, a loader, a feeder, a rotary drum, a discharging machine, a material crushing device, an induced draft fan, a discharger and a distribution cabinet; after the dehydrated wet material is added to the dryer, it is evenly dispersed in the dryer and fully contacted with the hot air under the tumbling of the evenly distributed scrapers in the drum, which accelerates the heat and mass transfer of drying. During the drying process, the material is discharged to the star-shaped discharge valve in the other section of the dryer under the action of the inclined scrapers and the hot air.

Specification

Spec.

(Dia.x Length mm) | Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air

Temperature(℃) | Rotate Speed(r/min) | Main Motor(kw) |

| Φ600x6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800x8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800x10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000x10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000x12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200x8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800x12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000x18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000x20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400x16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400x18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400x20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600x24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600x28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000x20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 85 |

| Φ3000x25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3200x25000 | 201 | 42.9-53.6 | 3~5 | 700~800 | 1.5~5 | 110 |