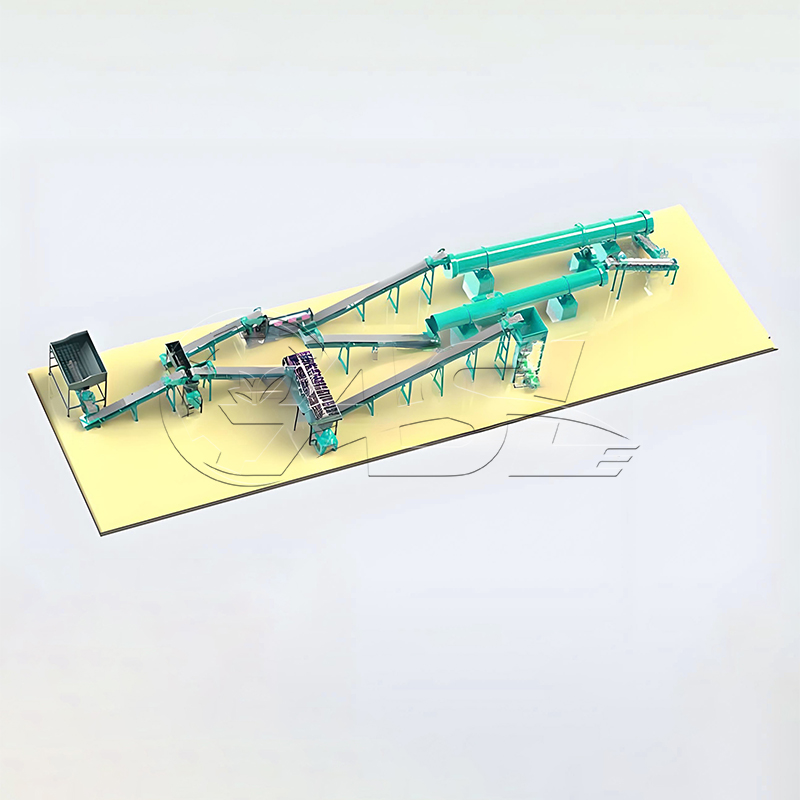

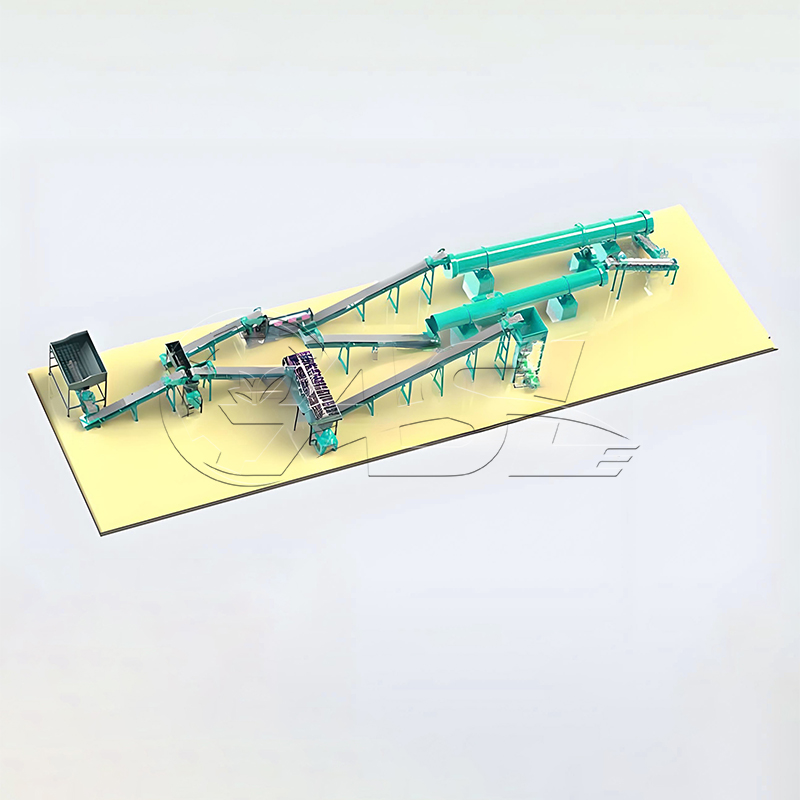

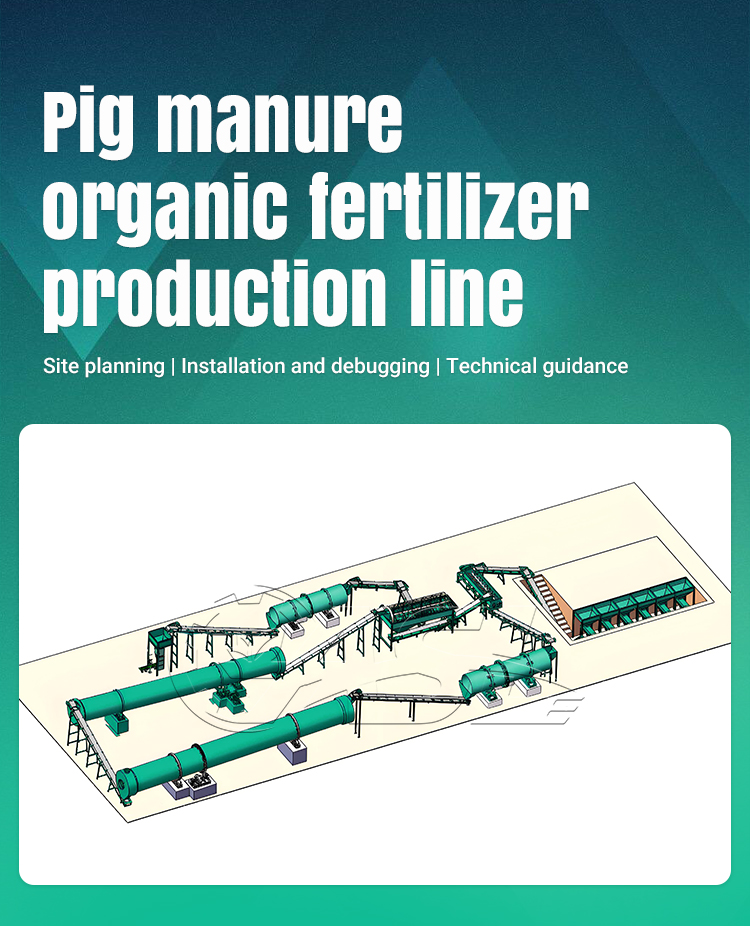

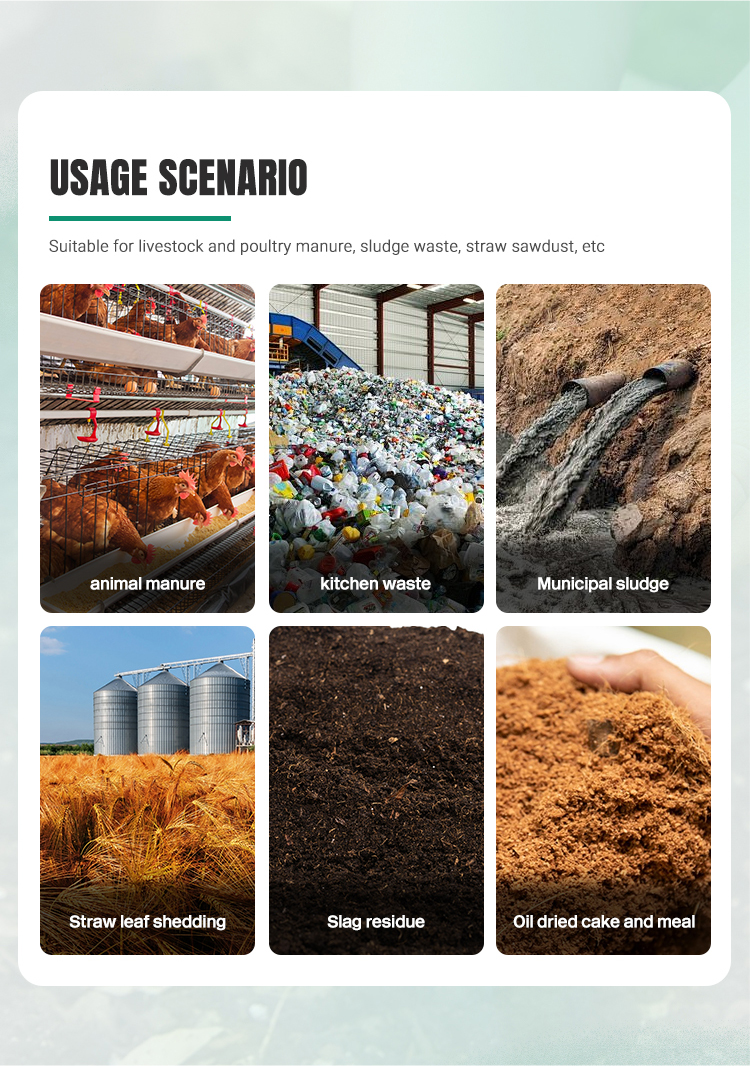

The pig manure organic fertilizer production line uses pig manure as raw material and is processed by a complete set of fertilizer production systems. The configuration plan can be selected according to the customer's production needs and a variety of advanced production processes: disc granulation, agitator granulation, powdered organic fertilizer and other equipment solutions.

1. Pig manure organic fertilizer contains organisms and enzymes that enhance the soil's biomass and enzyme activity, increasing soil nutrients and improving soil pH, making it suitable for the growth of various crops.

2. The organic fertilizer produced by the pig manure organic fertilizer production line is highly nutritious. If evenly distributed, it can last for at least 100 days without the need for additional fertilizer. This effect is unmatched by any other fertilizer.

3. Pest control agents can be added to the pig manure organic fertilizer production line during production to reduce disease, insect, and rodent infestations.

4. The organic fertilizer produced by the pig manure organic fertilizer granulator is highly nutritious. If evenly distributed, it can last for at least 100 days without the need for additional fertilizer. This effect is unmatched by any other fertilizer.

5. The organic fertilizer produced by the pig manure organic fertilizer production line is nutritionally comprehensive. In addition to the three major nutrients of nitrogen, phosphorus, and potassium, it is also rich in calcium, magnesium, and silicon, which improves soil composition and promotes crop growth.

The organic fertilizer production process is closely related to the equipment configuration of the production line. A typical complete set of equipment for an organic fertilizer production line consists of a fermentation system, drying system, deodorization and dust removal system, pulverization system, batching system, mixing system, granulation system, cooling and drying system, screening system, and finished product packaging system.

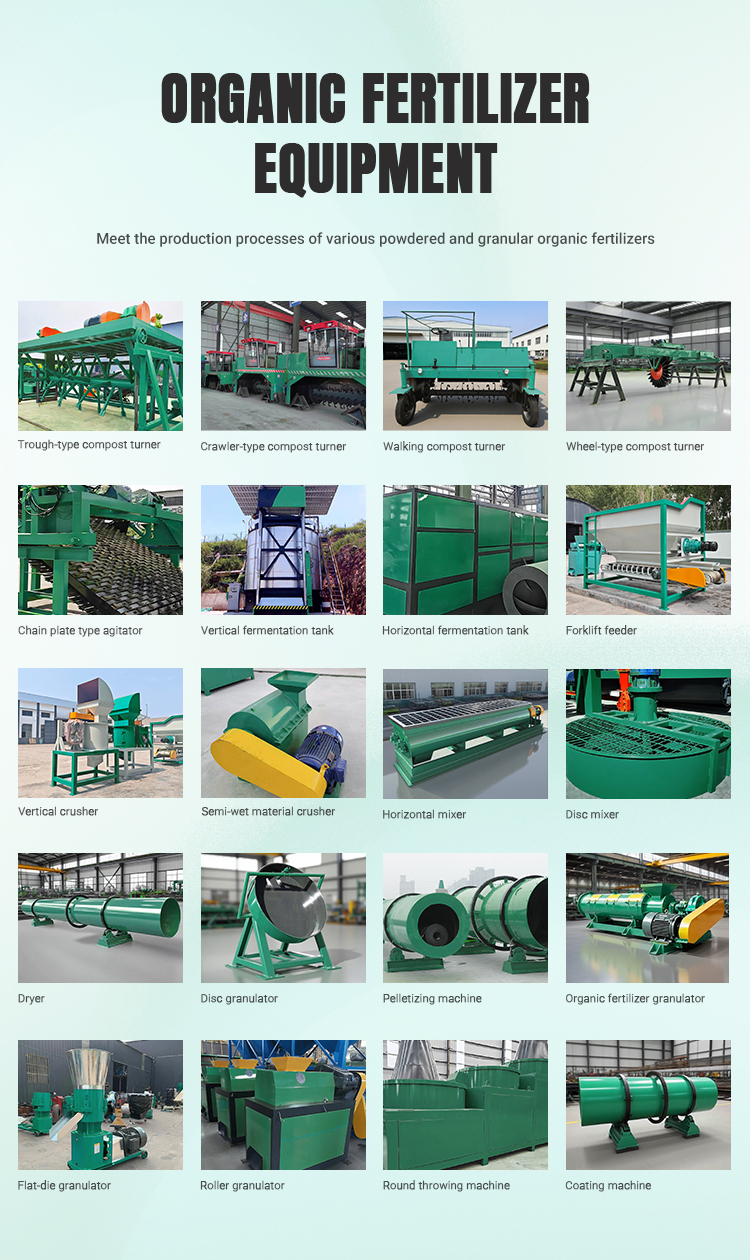

Drying System: The main equipment in the drying system includes a belt conveyor, a rotary dryer, a cooler, an induced draft fan, and a hot air furnace.

Deodorization and Dust Removal System: The deodorization and dust removal system consists of a settling chamber and a dust removal chamber. Free drawings are provided, and free installation guidance is provided.

Pulverization System: The pulverization system includes a new semi-wet material pulverizer, a chain pulverizer or cage pulverizer, and a belt conveyor.

Batching System: The batching system includes equipment such as an electronic batching system, a disc feeder, and a vibrating screen. It can handle 6-8 types of raw materials at a time.

Mixing System: The mixing system has optional The system consists of a horizontal mixer or pan mixer, a vibrating screen, and a mobile belt conveyor.

Granulation System: Compound fertilizer double-roller extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer granulator, rotary drum granulator, rounding machine, and compound fertilizer granulator.

Screening System: The screening system primarily utilizes a drum screen, which can be configured with a primary or secondary screen to increase yield and produce higher-quality granules.

Finished Product Packaging System: The finished product packaging system typically includes an electronic quantitative packaging scale, a silo, and an automatic bag sewing machine. This allows for fully automated, non-stop

production of the organic fertilizer production line.

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap