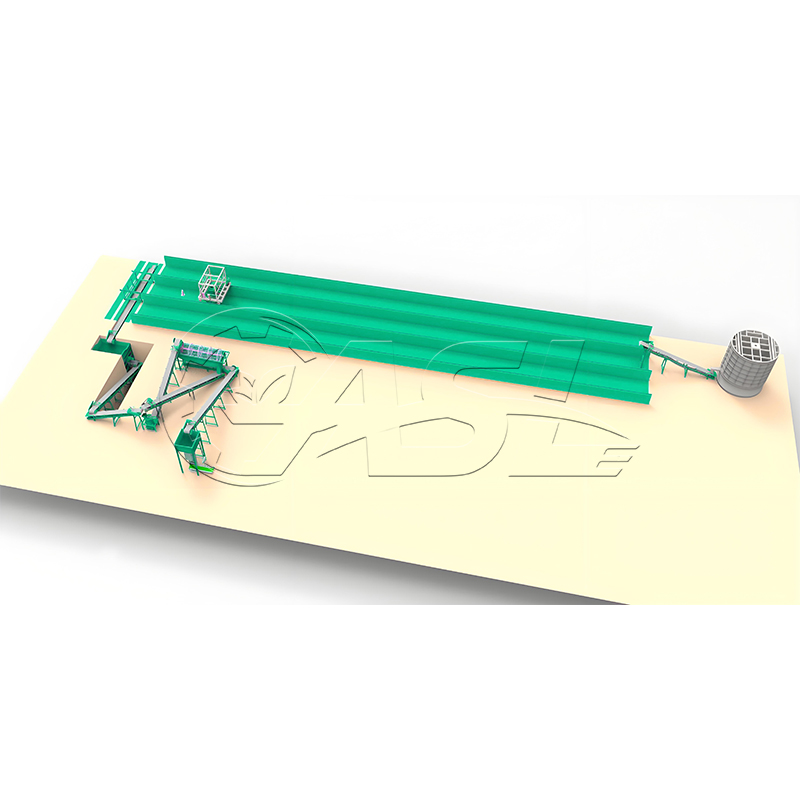

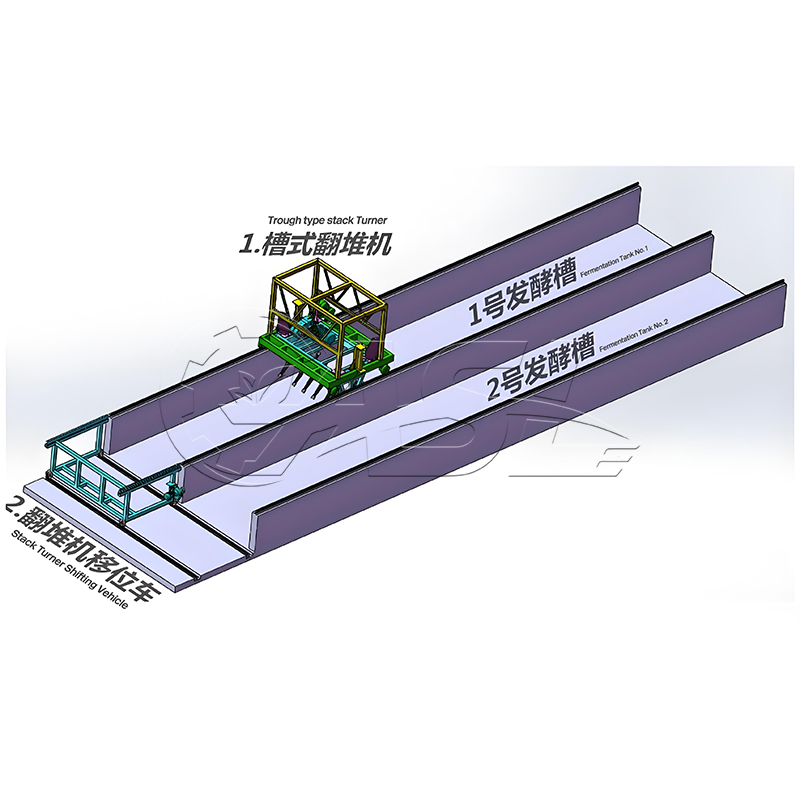

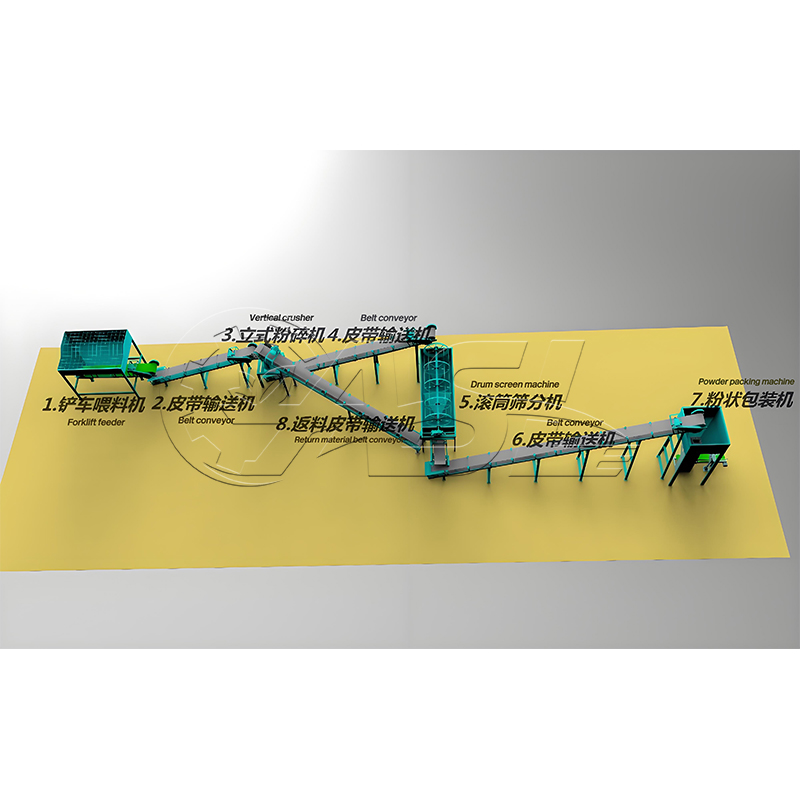

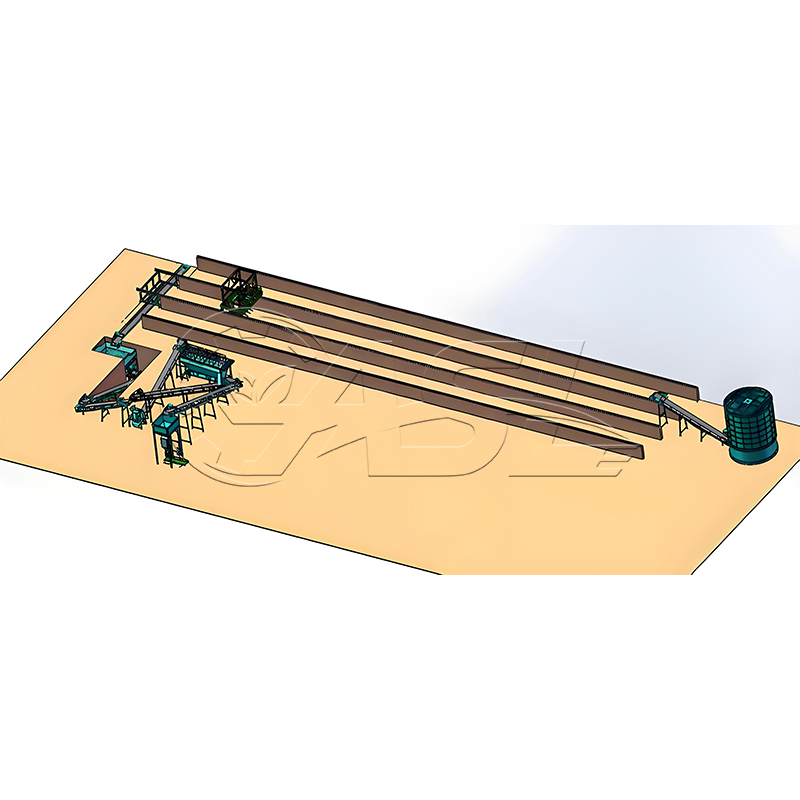

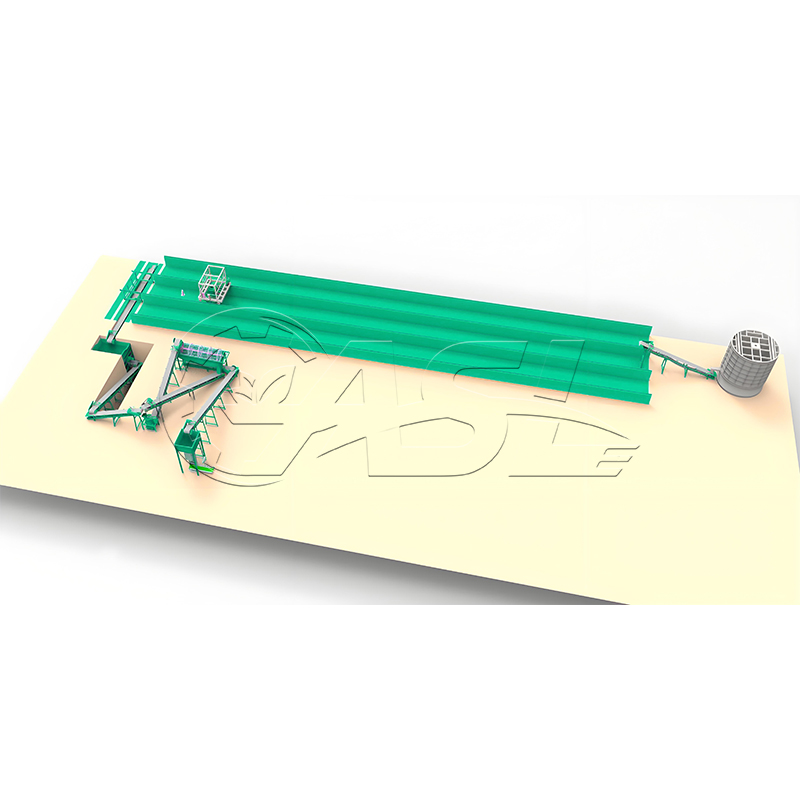

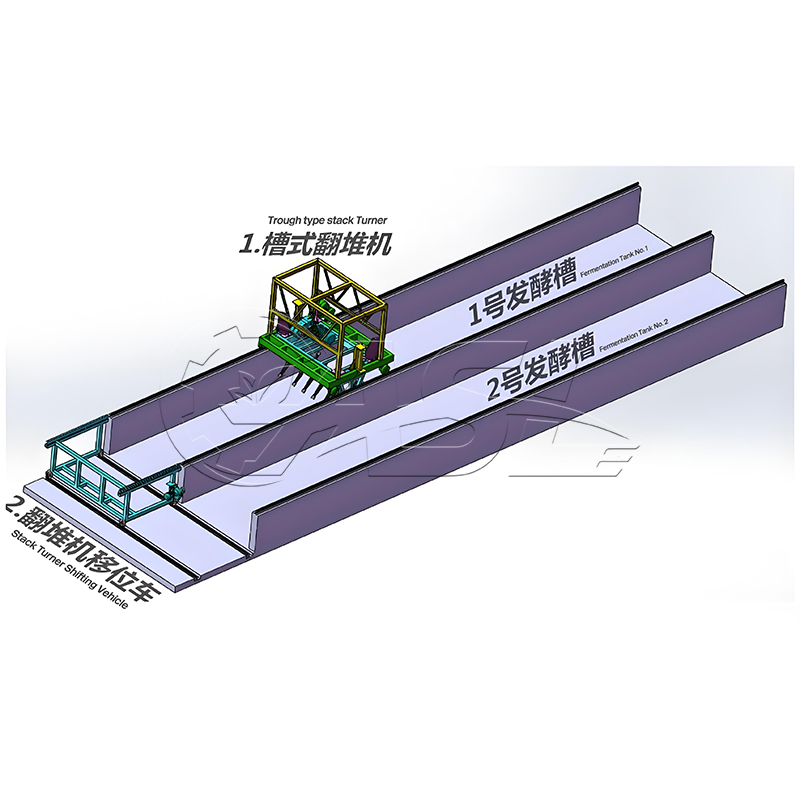

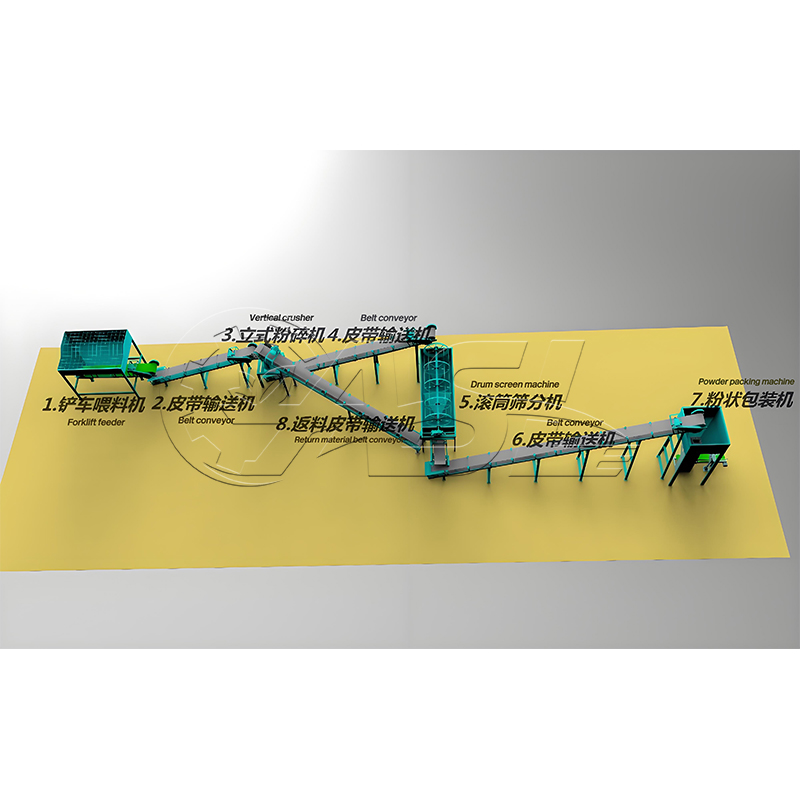

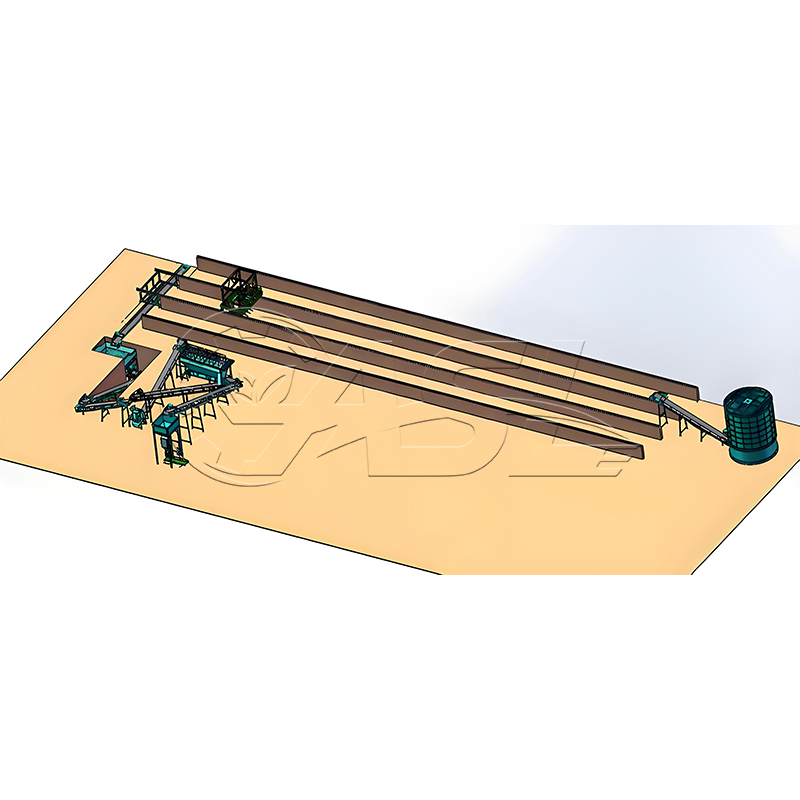

The production of powdered organic fertilizer is relatively simple. The main production equipment consists of five major components: organic fertilizer turning machine, forklift, quantitative feeder, crusher, and screening machine (roller screen or vibrating screen). These equipment need to be connected by four sets of belt conveyors to form a complete production line. 1. A set of belt conveyor above the crusher connects the large-sized raw materials that have been screened. 2. A belt above the screening machine connects the fermentation materials. 3. A belt below the screening machine connects the finished products after screening, transporting them to the processing location for weighing and packaging. 4. A conveyor is needed in the warehouse for loading.

1. Agricultural waste: such as straw, soybean meal, cottonseed meal, etc.

2. Livestock and poultry manure: such as chicken manure, cattle and sheep manure, rabbit manure.

3. Industrial waste: such as wine lees, vinegar lees, cassava residue, sugar residue, furfural residue, etc.

4. Domestic waste: such as kitchen waste, etc.

5. Urban sludge: such as river sludge, sewer sludge, etc. Duck manure organic fertilizer production line, sludge organic fertilizer production line, earthworm manure organic fertilizer production line

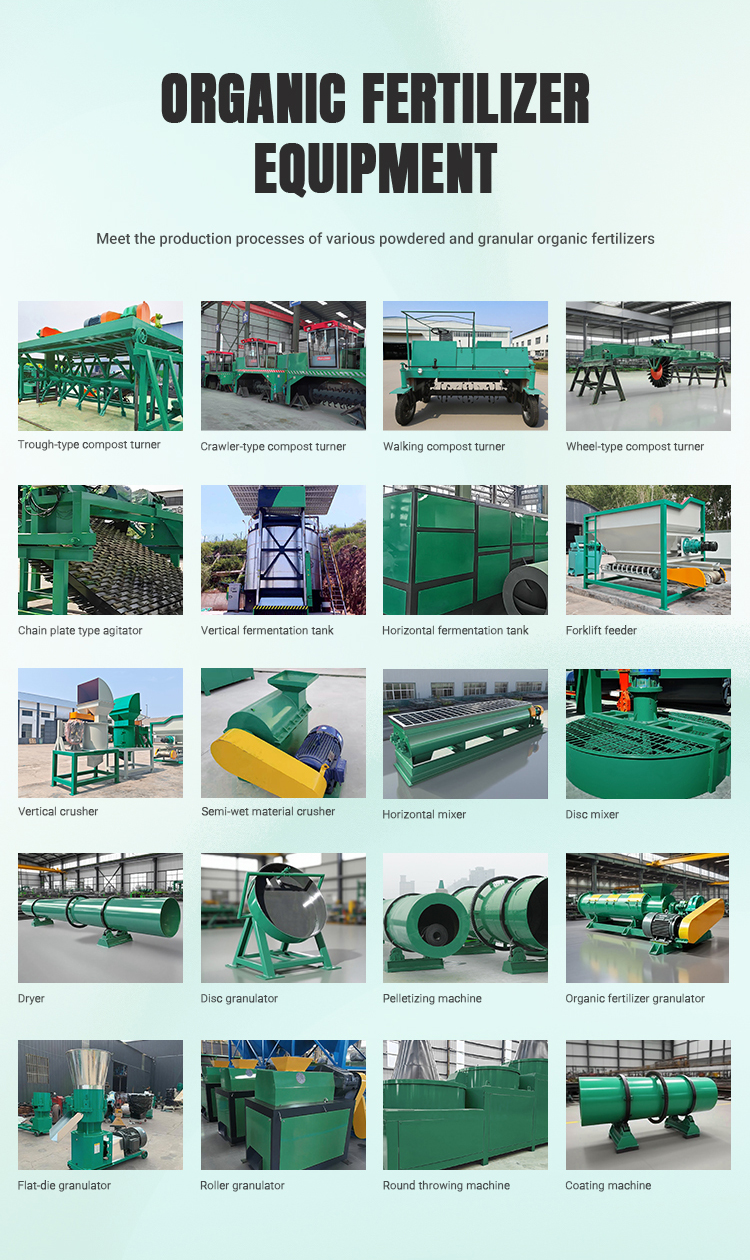

The organic fertilizer production line includes extrusion granulator, roller granulator, drum screen, high-humidity material dryer, BB fertilizer blender, roller compound fertilizer granulator, fermentation compost turning

machine, BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) ball granulator, drum screening machine, cage crusher, roller extrusion granulator, BB fertilizer

production line. Duck manure organic fertilizer production line, sludge organic fertilizer production line, earthworm manure organic fertilizer production line

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap