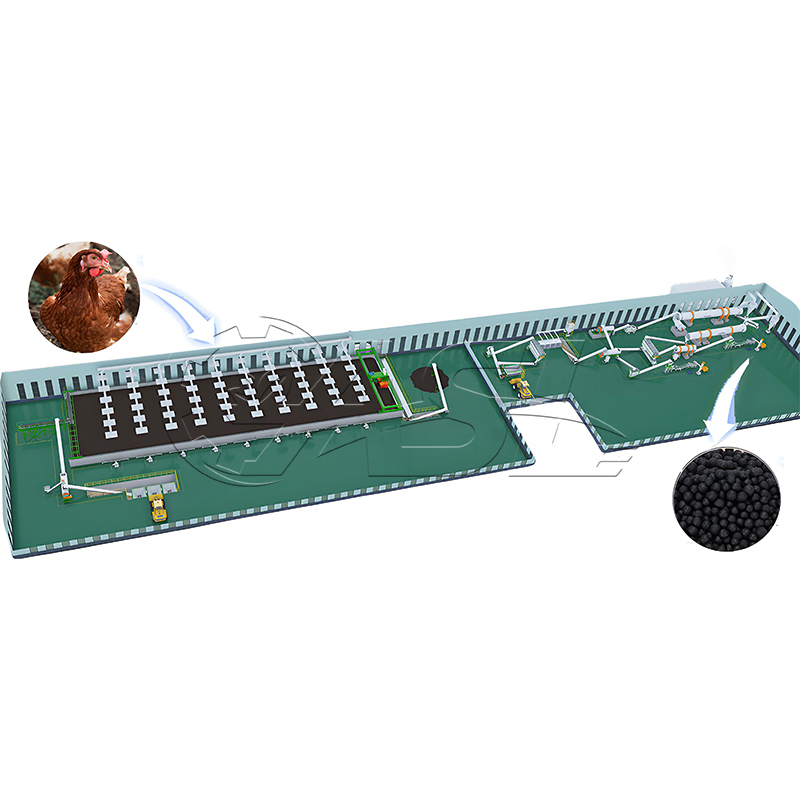

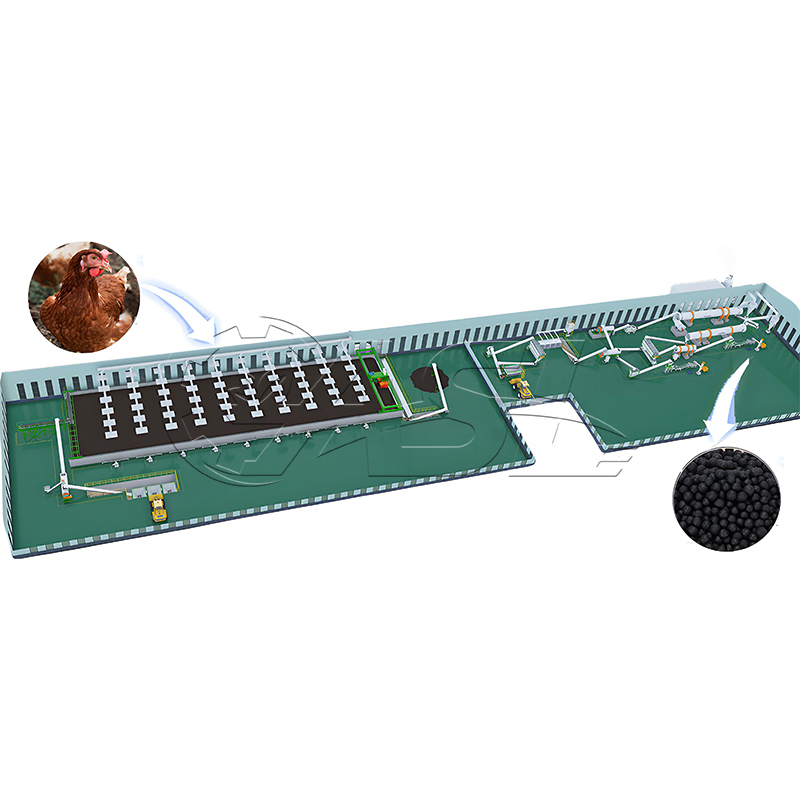

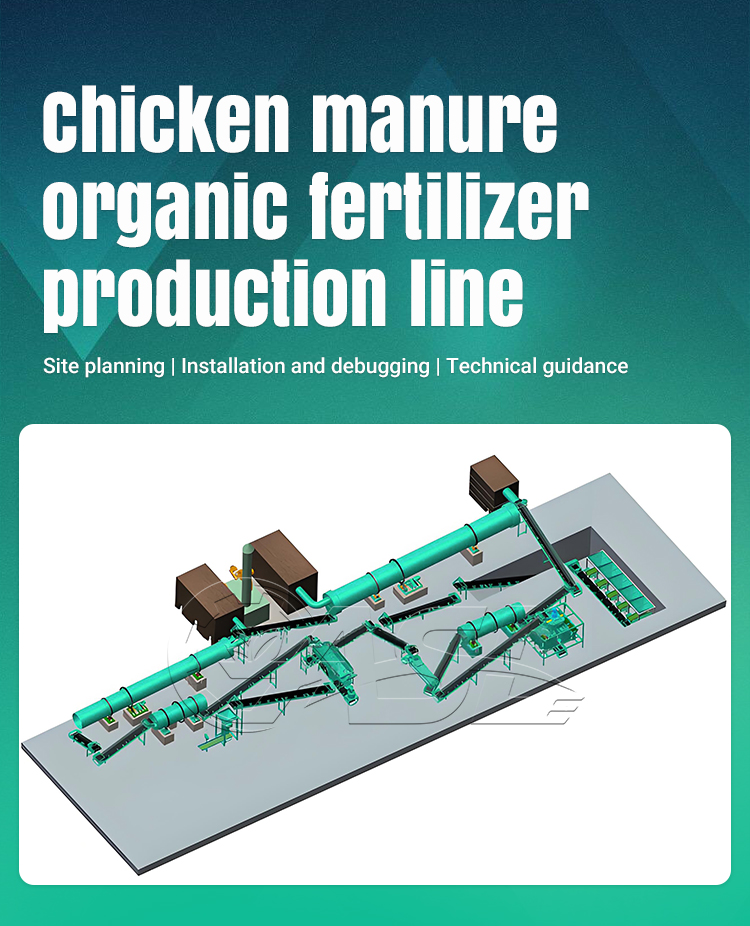

The chicken manure organic fertilizer production line uses chicken manure as raw material, processed through a complete fertilizer production system. Configuration options are tailored to customer production needs and include a variety of advanced production processes, including disc granulation, agitator granulation, and powdered organic fertilizer.

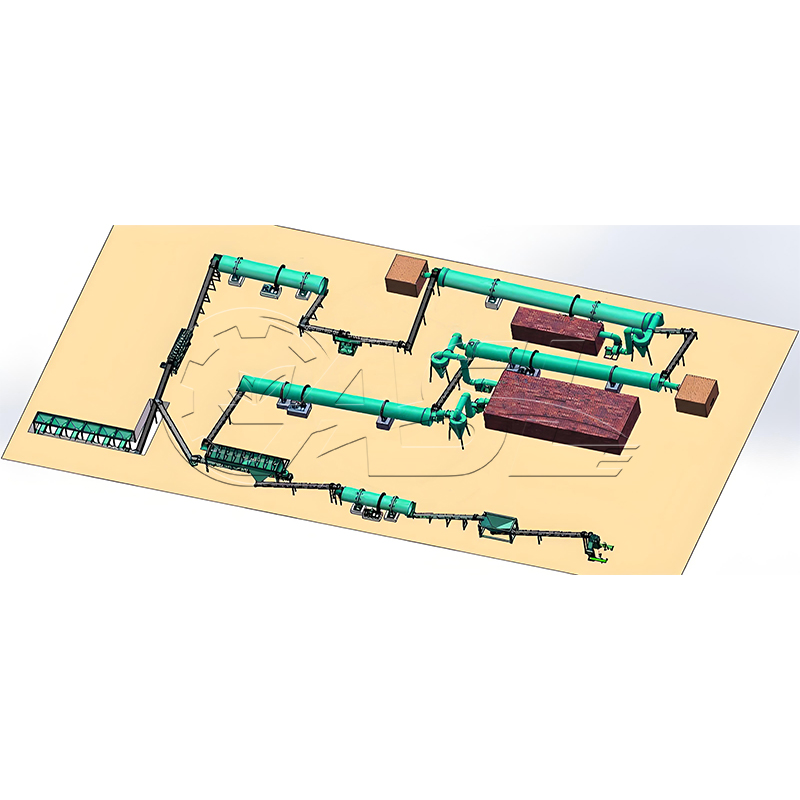

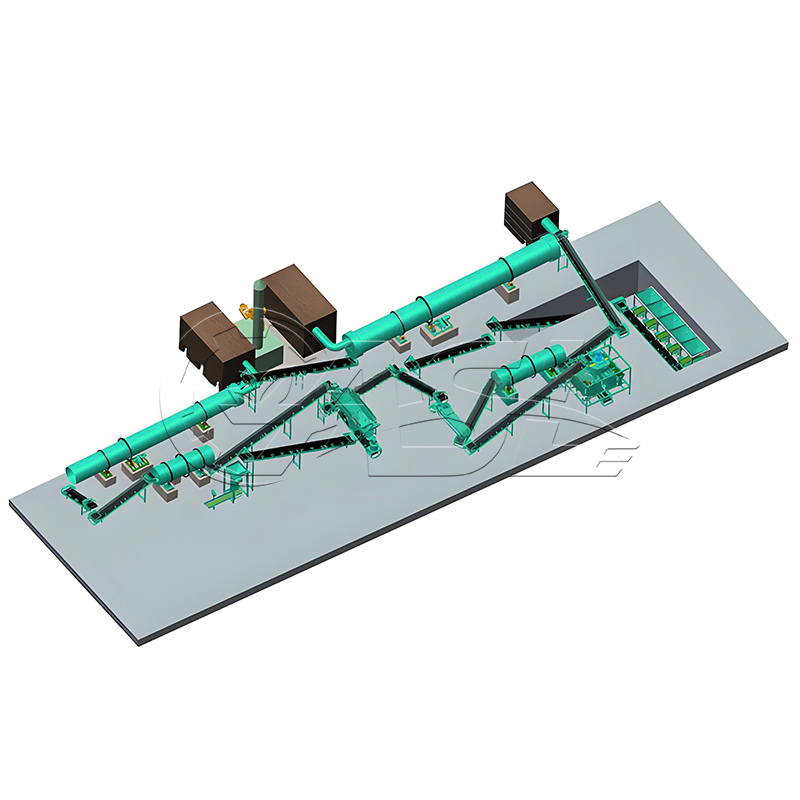

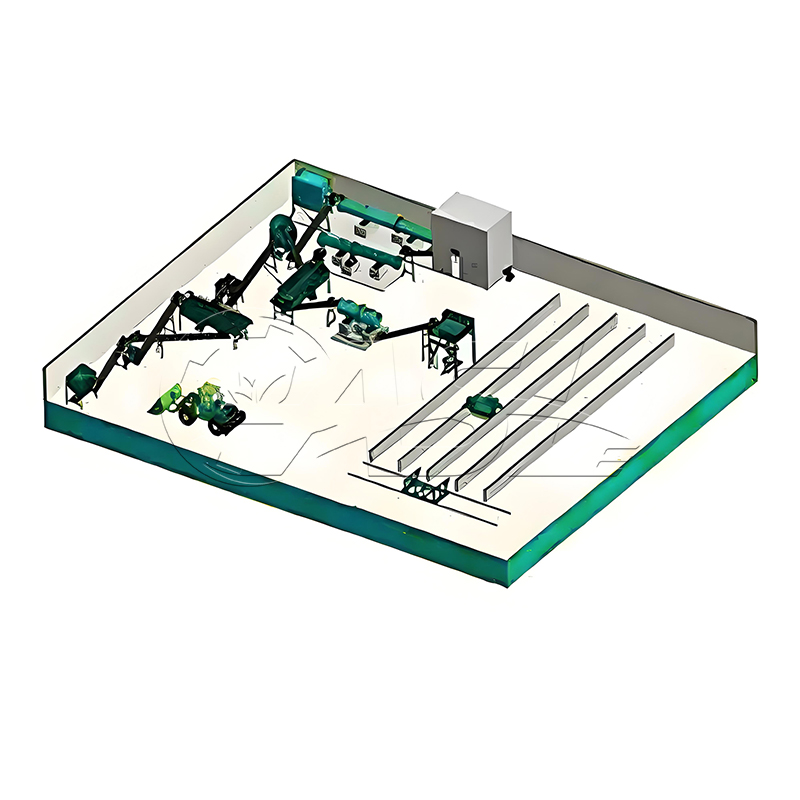

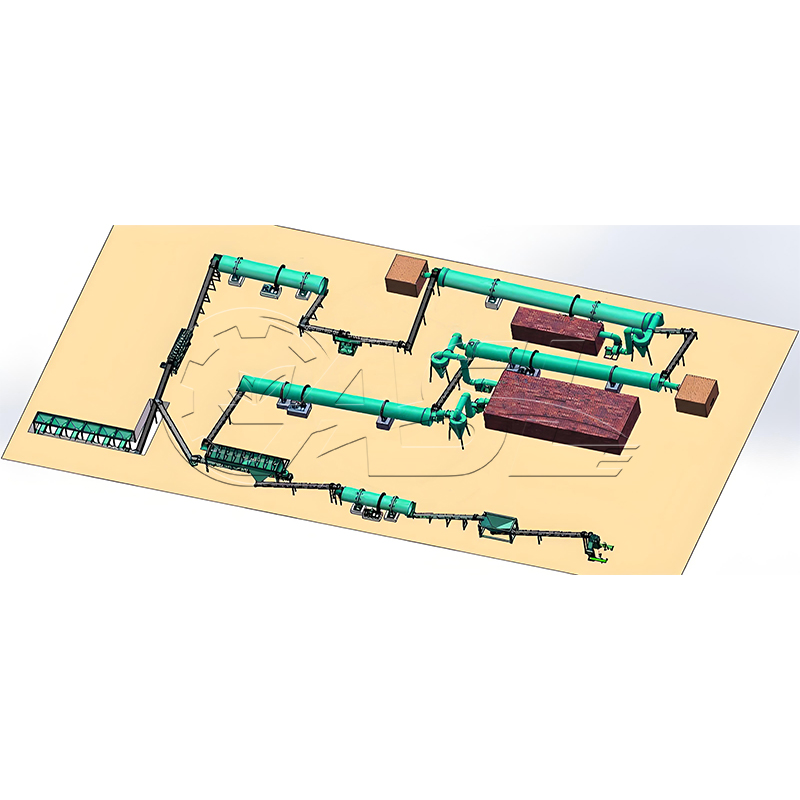

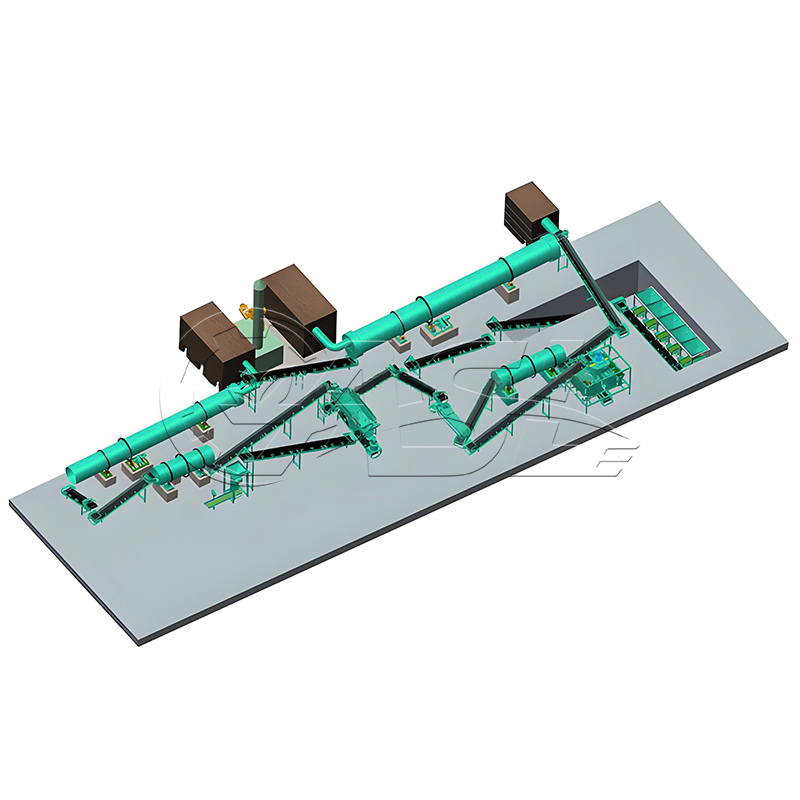

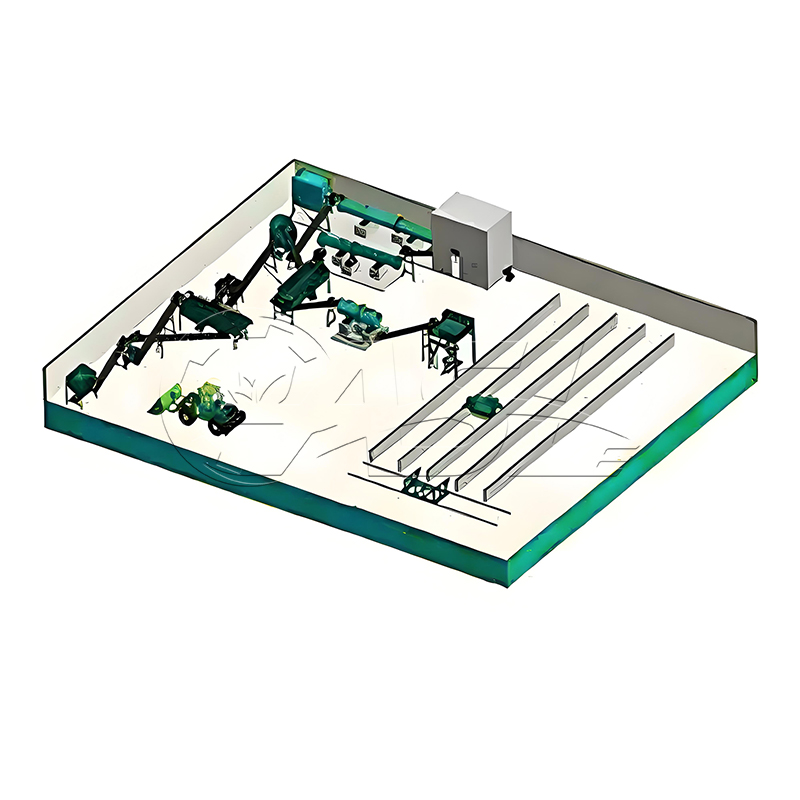

Chicken manure is a relatively high-quality organic fertilizer, containing approximately 1.63% pure nitrogen, 1.54% phosphorus (P2O5), and 0.085% potassium (K2O). Before application, chicken manure must be composted with a composting agent. This process inactivates and deodorizes parasites and their eggs, as well as infectious pathogens. The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. A typical complete set of organic fertilizer production lines consists of a fermentation system, drying system, deodorization and dust removal system, pulverization system, batching system, mixing system, granulation system, screening system, and finished product packaging system. The production process of chicken manure organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

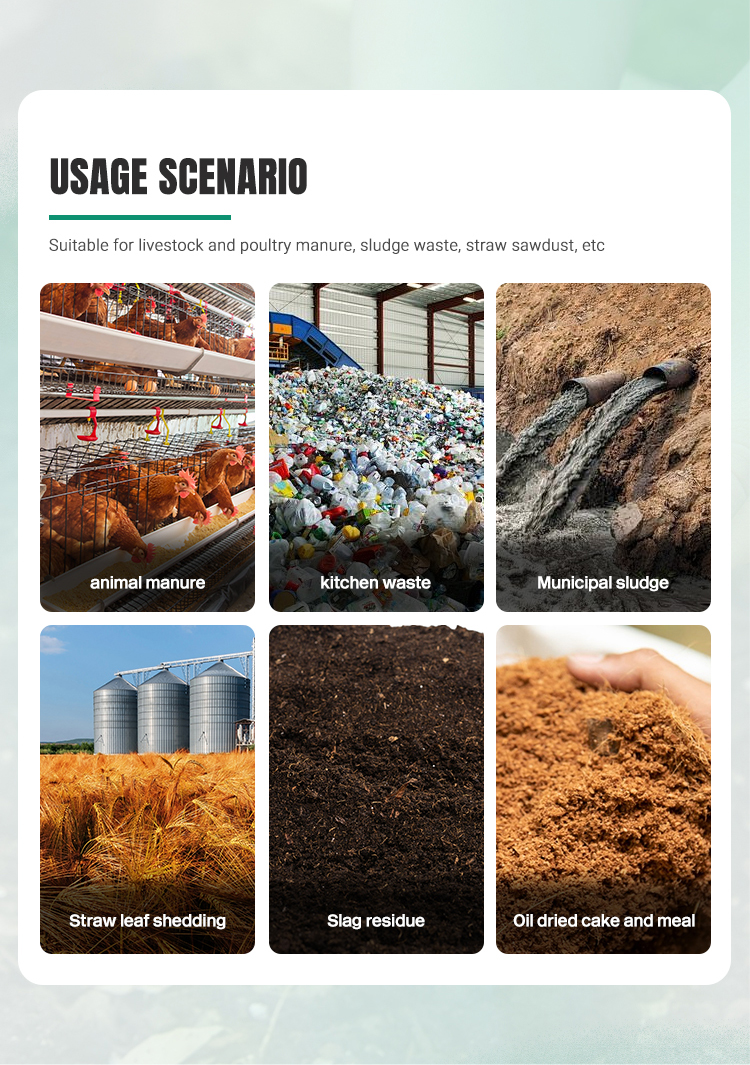

1. Agricultural waste: such as straw, soybean meal, cottonseed meal, etc.

2. Livestock and poultry manure: such as chicken manure, cattle and sheep manure, rabbit manure.

3. Industrial waste: such as wine lees, vinegar lees, cassava residue, sugar residue, furfural residue, etc.

4. Domestic waste: such as kitchen waste, etc.

5. Urban sludge: such as river sludge, sewer sludge, etc. Duck manure organic fertilizer production line, sludge organic fertilizer production line, earthworm manure organic fertilizer production line

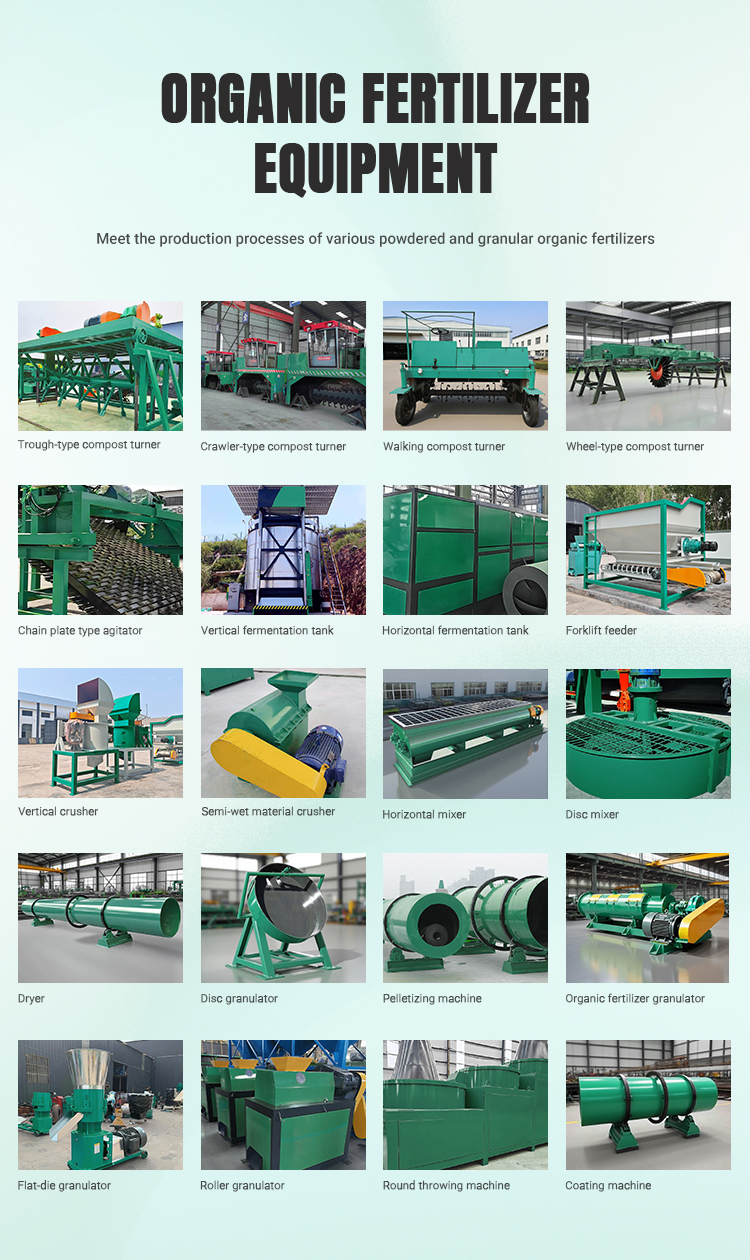

The organic fertilizer production line includes extrusion granulator, roller granulator, drum screen, high-humidity material dryer, BB fertilizer blender, roller compound fertilizer granulator, fermentation compost turning

machine, BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) ball granulator, drum screening machine, cage crusher, roller extrusion granulator, BB fertilizer

production line. Duck manure organic fertilizer production line, sludge organic fertilizer production line, earthworm manure organic fertilizer production line

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap