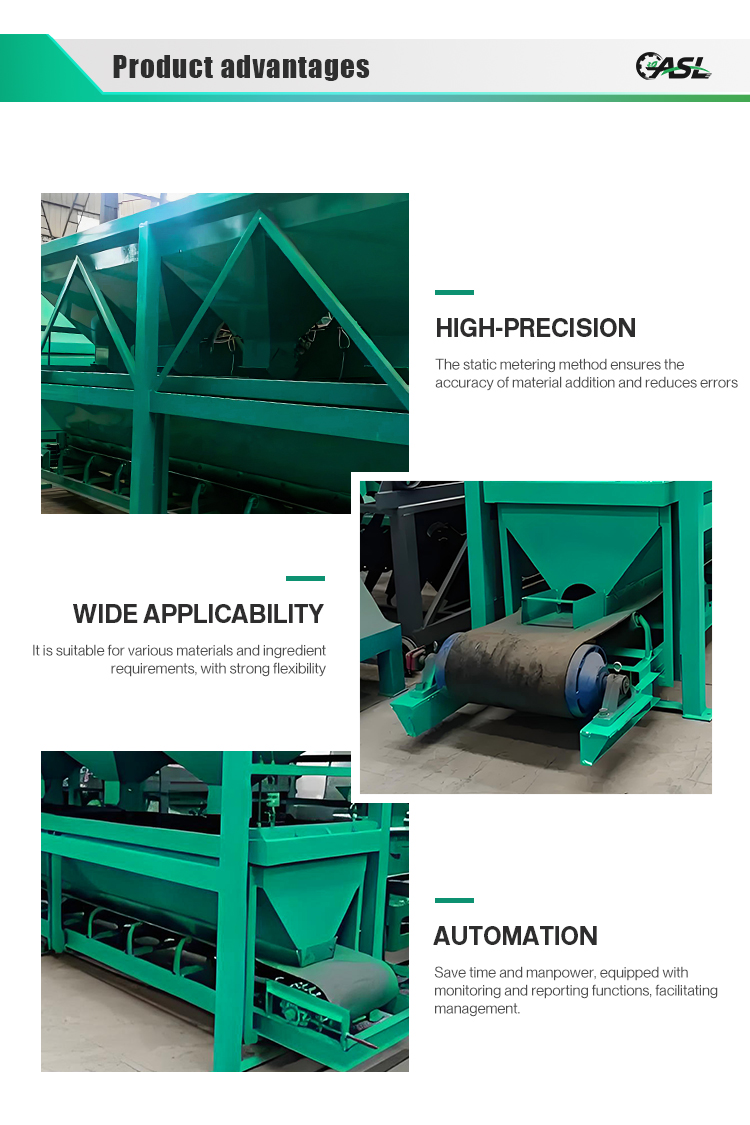

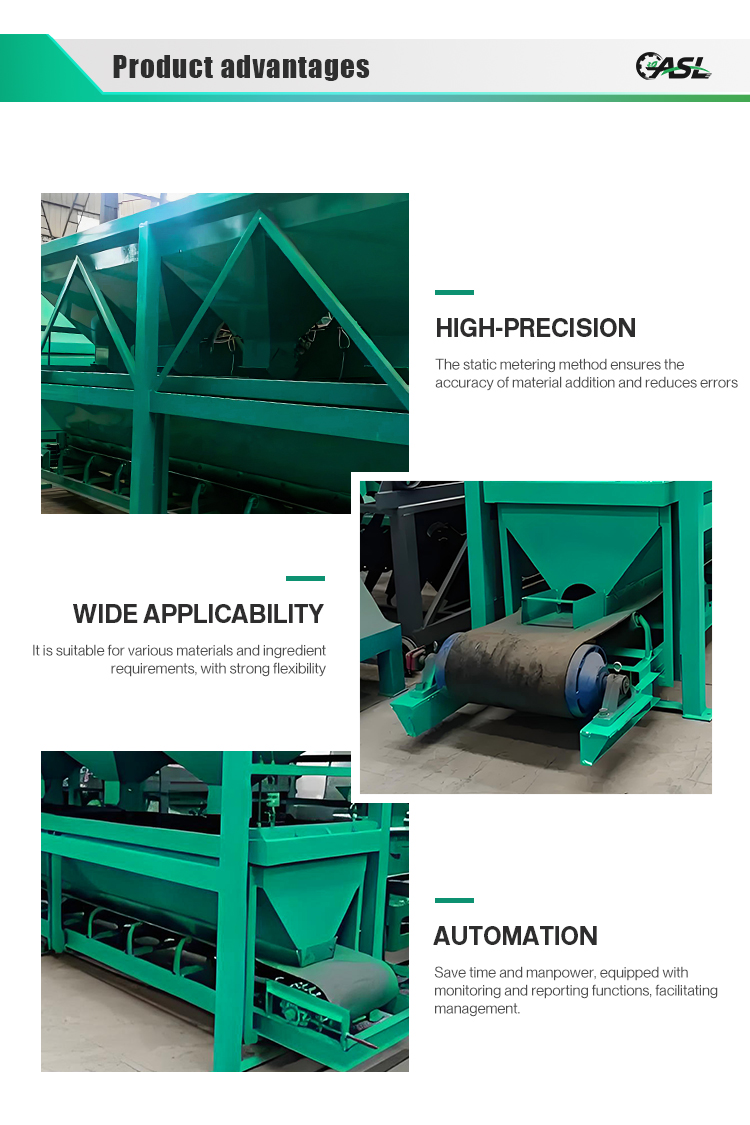

It is suitable for fertilizer production lines of various sizes. It effectively ensures batching accuracy and improves productivity. Its simple structure is reliable, easy to operate and maintain, and its accurate metering effectively guarantees the quality of organic and compound fertilizers. The electronic batching machine is a new type of batching machine suitable for general organic and compound fertilizer manufacturers.

The weighing system of the automatic batching machine utilizes a weight controller and sensors to quantitatively measure, batch, and control materials, and automatically adjust for drop differences. The automatic batching machine offers advantages such as a rational layout, compact structure, simple operation, precise batching, and reliable control.

Automatic batching machines are automated equipment for quantitatively distributing organic fertilizer raw materials. They are primarily used in the fertilizer production industry, replacing manual scales or volumetric metering.

They feature high metering accuracy, efficient dispensing, and a high degree of automation. They are a key component of fertilizer production equipment and fully automatic concrete mixing plants.

Static batching machines, with their core advantages of high precision, flexible operation, and easy maintenance, are the cost-effective choice for small and medium-sized organic fertilizer production lines.