What materials are suitable for compost turning with a trough-type compost turning machine?

Trough-type compost turning machines are suitable for composting and turning organic waste such as livestock and poultry manure (such as chicken, cow, and pig manure), sludge, sugar factory filter mud, grain cake, straw, and sawdust. They are widely used in organic fertilizer plants, compound fertilizer plants, sludge and waste treatment plants, horticultural farms, and Agaricus bisporus cultivation facilities for fermentation, composting, and moisture removal. For example, on livestock farms, livestock and poultry manure can be processed through a trough-type compost turning machine and converted into high-quality organic fertilizer raw material. "

What are the characteristics of different types of trough compost turners?

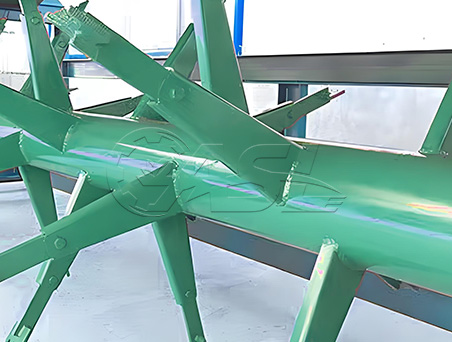

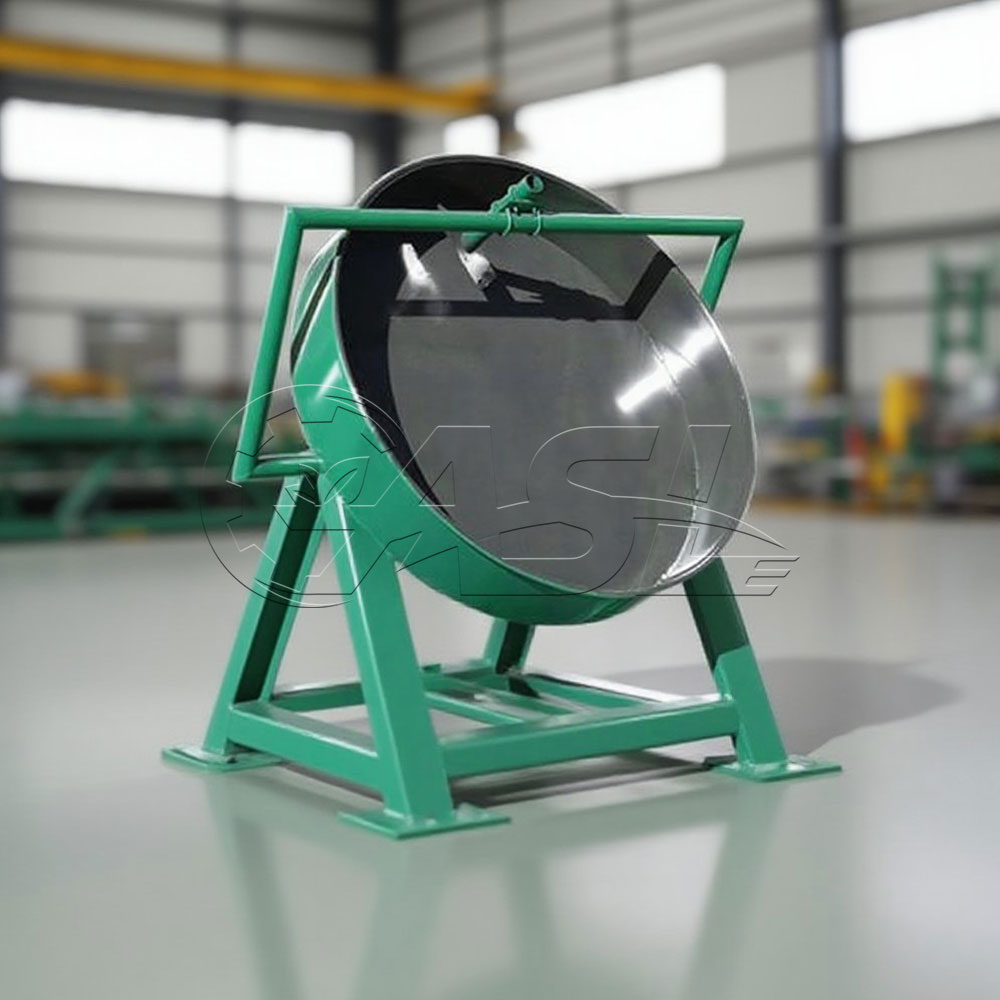

Wheel-disc trough turners: These consist of multiple wheels that travel over the material and perform the turning operation. The rotation of the wheels lifts and disperses the material, achieving ventilation and mixing. They are highly maneuverable and suitable for small and medium-sized fermentation sites. They require relatively little space and can operate on irregular terrain.

Crawler-type trough turners: These use tracks to travel over the material and use a special turning mechanism to turn the material. The track design provides excellent maneuverability and stability, with strong turning force, making them suitable for handling thicker piles. They are also easy to operate and can be remotely controlled.

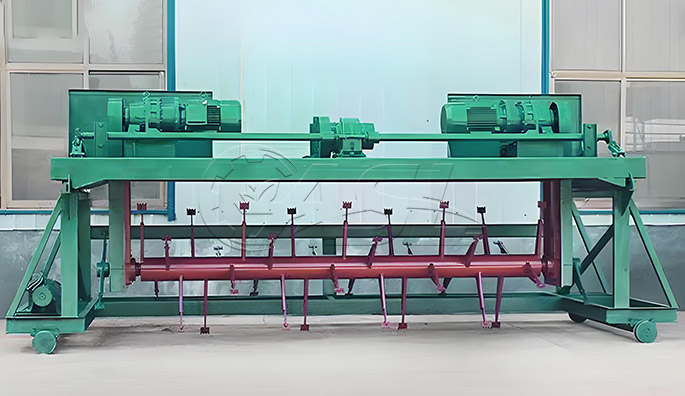

Track-type trough turners: These run along a pre-set track to turn the material. They are suitable for large-scale, continuous organic fertilizer production, featuring a high degree of automation and reduced manual operation.

How to choose the right size trough turner?

First, consider the scale of the material to be processed. If the farm is large and the livestock and poultry manure production is high, a large-scale machine with a high processing capacity, such as one capable of processing 100-500 tons per day, will be required. Secondly, consider site conditions. If space is limited, choose a model with a smaller footprint. If the site is open and well-organized, a track-type compost turner can better leverage its continuous operation advantages. Material characteristics are also crucial. For example, if the material is highly sticky or hard, choose a machine with a strong turning force and wear-resistant blades.

What precautions should be taken when using a trough-type compost turner?

During operation, coordinate the movement of each hydraulic cylinder to ensure smooth turning. Avoid tipping the pile too quickly, causing large fragments or raising dust. During turning, carefully observe the pile to avoid excessive stirring. Keep hard debris (such as rebar and rocks) out of the material to avoid damage to components such as the turning teeth. Keep the pile height within 80% of the rated depth of the machine to avoid prolonged overload.