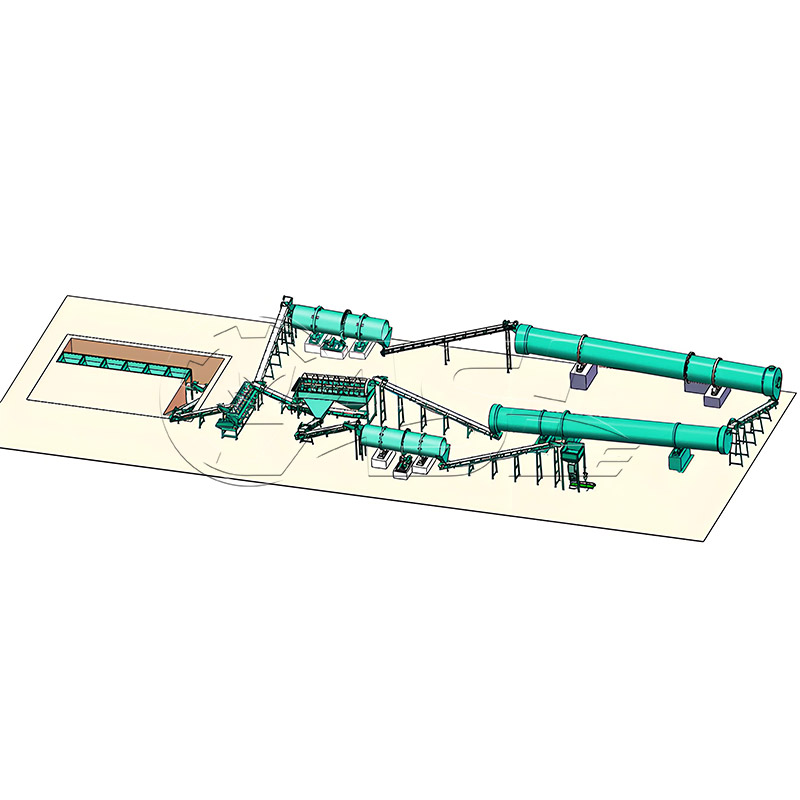

What raw materials can the production line process? What is the required moisture content?

The organic raw materials it can process cover a wide range of sectors, including agriculture, animal husbandry, and industry. These include livestock manure from pigs, cattle, sheep, and chickens, corn/wheat straw, mushroom residue from edible fungus cultivation, dewatered sludge from municipal sewage treatment, and distiller's grains, bean dregs, and fruit residue from food processing. The core material is suitable for wet materials with a moisture content of 25%-40%. Unlike extrusion granulators, there is no need to pre-dry the material to below 15%, significantly reducing pre-processing steps and energy consumption.

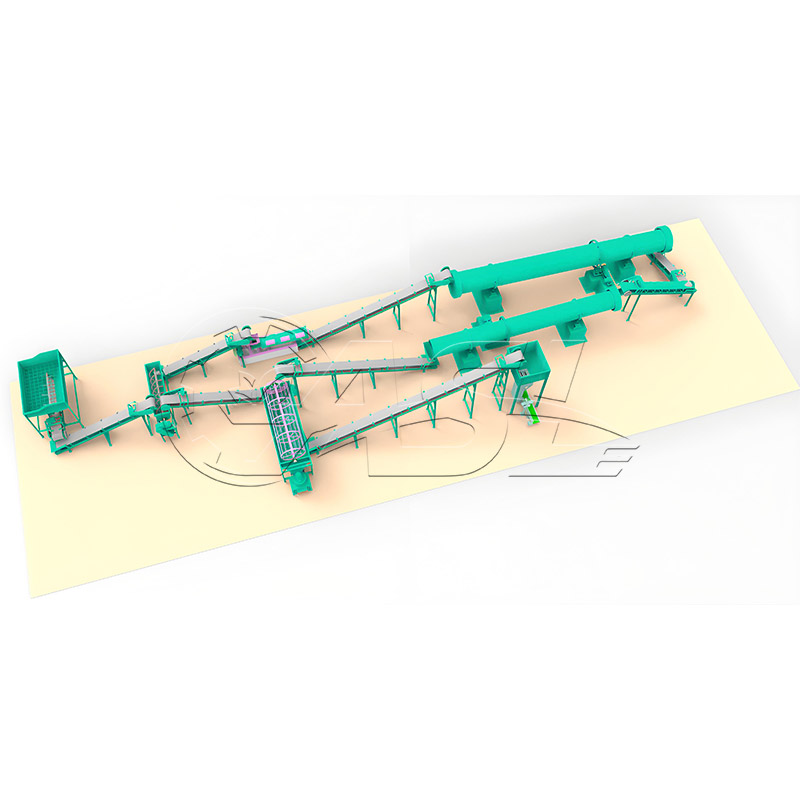

What is the output of a single production line? What scale of production can it meet?

The hourly output of a single core device ranges from 1 to 15 tons. The model can be selected based on user needs: Devices with an hourly output of 1 to 3 tons are suitable for home-based workshops or small farms, meeting the fertilizer needs of farmland within 500 mu (approximately 16 acres). Devices with an hourly output of 4 to 7 tons are suitable for medium-sized organic fertilizer plants, serving the regional planting market. Large-scale production lines with an hourly output of 8 to 15 tons can support large-scale organic fertilizer processing companies, enabling nationwide distribution and sales.

Can the particle size of the finished granules be adjusted? What are their shape and strength?

The particle size of the finished granules can be flexibly adjusted by replacing the screen within the device. Fine granules are suitable for delicate cultivation applications such as vegetable seedlings and potted flowers; medium granules are suitable for cash crops such as fruit trees and tea plantations; and coarse granules are more suitable for field crops such as wheat and corn. The granules are nearly spherical and have good flowability, facilitating subsequent packaging, transportation, and field spreading. With a compressive strength of 1.5-2.5 MPa, they resist breakage during stacking and transportation, with a breakage rate typically below 5%. The granules retain uniform pores, allowing them to quickly absorb water and allow air to pass through the soil, promoting the slow release of nutrients and extending the fertilizer's effectiveness.

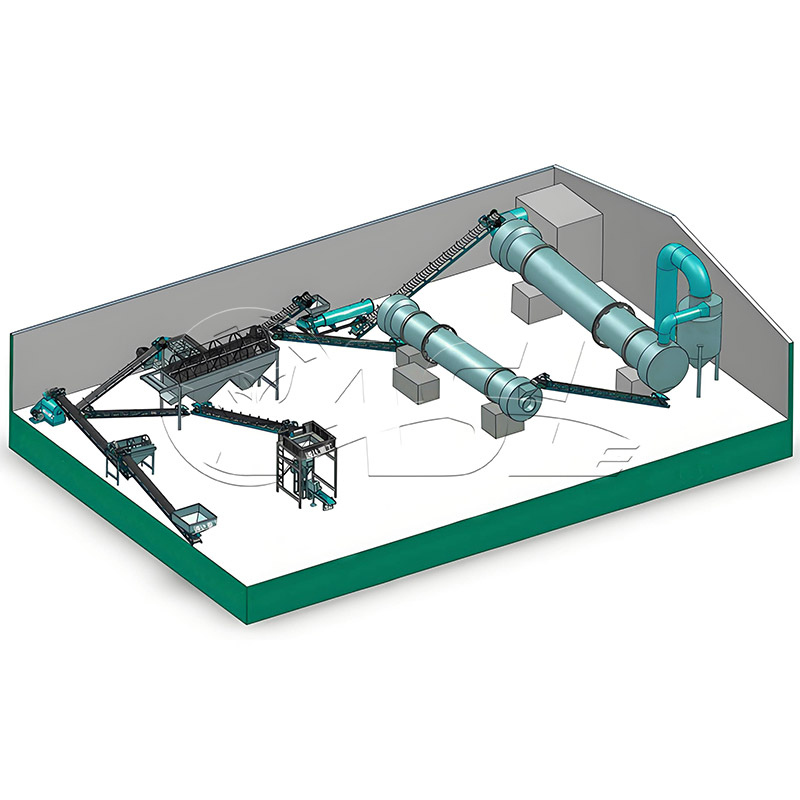

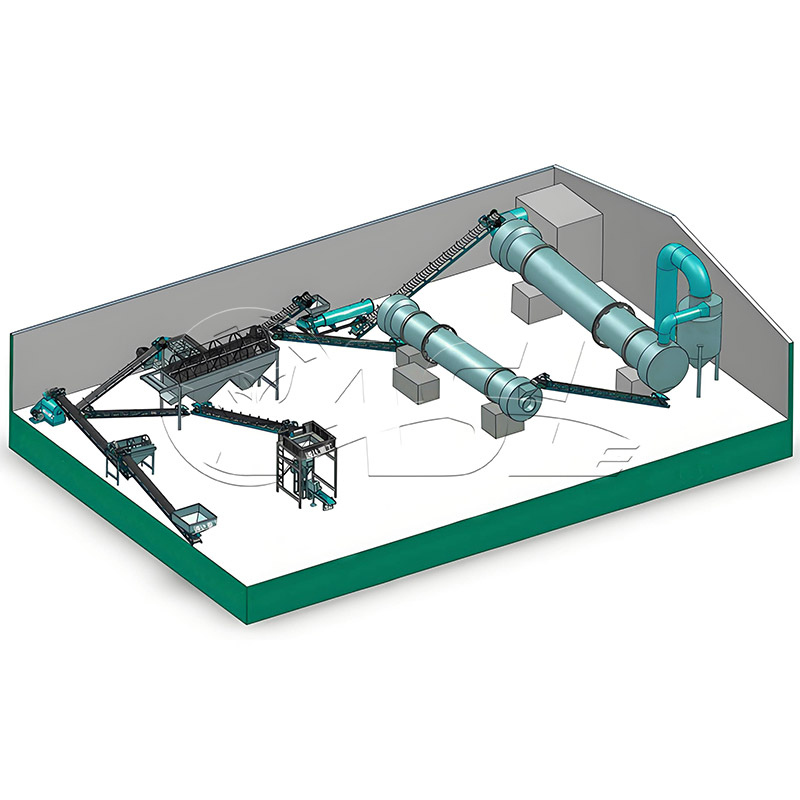

Will odor or dust be generated during the production process? How is this handled?

The accompanying deodorization system (spraying + biofilter) and dust collector (pulse bag type) effectively control odor and dust emissions, complying with environmental standards and preventing secondary pollution.

Can the production line produce different types of organic fertilizers, such as bio-organic fertilizers and compound fertilizers?

Yes; by adjusting the raw material formula, we can produce bio-organic fertilizers and organic-inorganic compound fertilizers to meet different market needs.