What standards can a BB fertilizer blender achieve for mixing uniformity?

High-quality BB fertilizer blenders achieve high mixing uniformity, generally with a coefficient of variation (CV) of ≤5%. This ensures uniform distribution of nutrients in the blended fertilizer, meeting the stringent fertilizer quality requirements of agricultural production and ensuring consistent and stable fertilization results. For example, a twin-helix conical mixer typically achieves a CV of ≤3%, making it ideal for producing high-precision blended fertilizers.

How adaptable are blenders to different material properties?

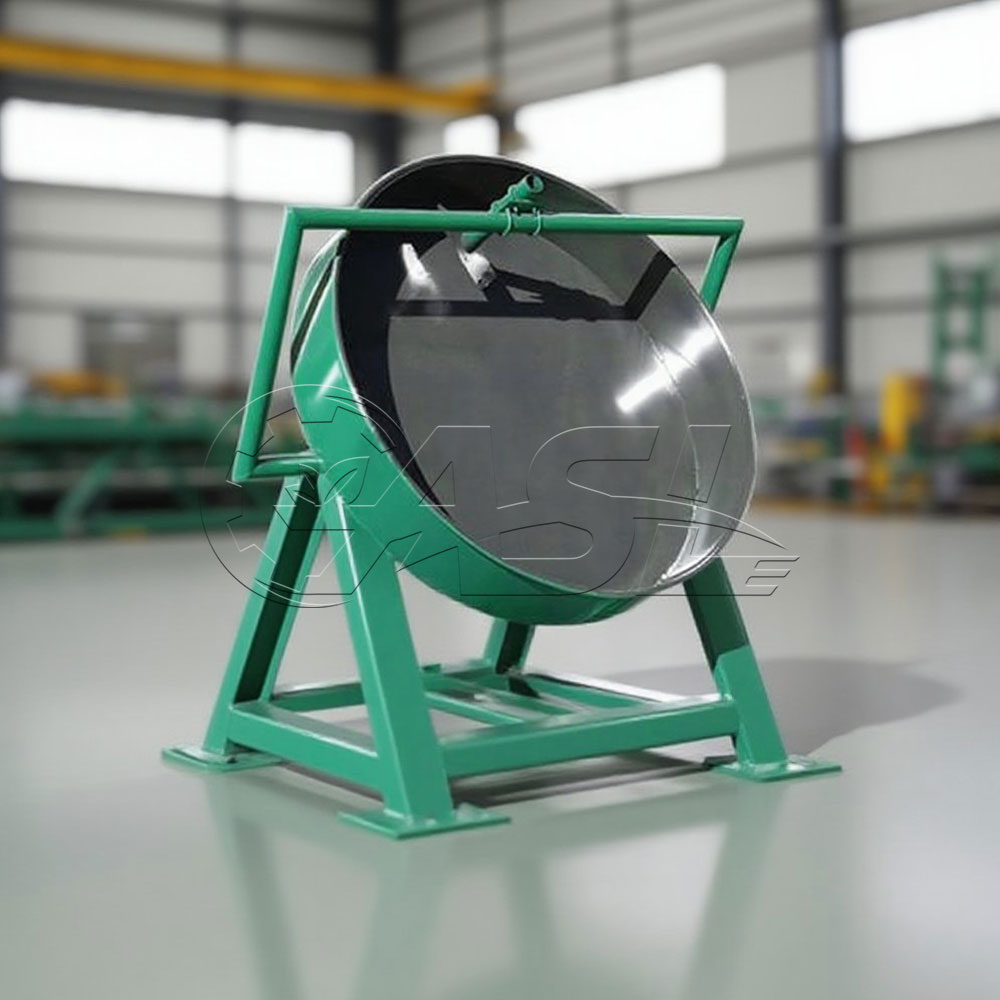

1. For materials with large variations in particle hardness and density, a three-dimensional mixer, such as a twin-helix conical mixer, is preferred. This mixer utilizes the combined rotation and revolution of the twin propellers to achieve three-dimensional convection mixing, effectively overcoming the problem of uneven mixing caused by density differences.

2. For coated fertilizers, since their particles are easily broken, equipment with a low particle breakage rate should be selected, such as a drum mixer. Its rotating drum creates free-fall mixing, effectively protecting the integrity of the coated fertilizer during mixing. 3. For blended fertilizers containing powdered raw materials, if the raw materials are slightly clumped, a vertical crusher-mixer is more suitable. It combines crushing and mixing functions and can handle clumped materials. However, please note that this type of equipment consumes relatively high energy.

What precautions should be taken when operating a BB fertilizer mixer?

1. Before operation, thoroughly inspect all equipment components to ensure they are properly grounded and that the electrical, hydraulic, and pneumatic systems are functioning properly. Clean any debris from valves, oil pumps, and drive shafts and add lubricant. Also, check the quality of the raw materials.

2. During operation, strictly follow the equipment's operating and safety procedures to ensure smooth operation and avoid abnormal noise and vibration. If any equipment malfunction occurs, stop the equipment immediately and investigate for the fault. If the severity of the problem cannot be determined, contact maintenance personnel promptly.

3. Before shutting down the equipment, stop all operations, clean any debris from the equipment surface, and perform maintenance.

What is the maintenance cycle and content for a mixer?

1. Daily Maintenance: Inspect the equipment's electrical, hydraulic, and pneumatic systems, clean the equipment's exterior and interior, promptly discharge exhaust and waste fluids, add lubricant, and remove debris from valves, oil pumps, and drive shafts.

2. Weekly Maintenance: Regularly check the equipment's safety devices for integrity, electrical wiring for tightness, and lubricant levels, replacing them promptly.

3. Monthly Maintenance: Maintain the equipment's moving parts, regularly clean and lubricate them, regularly inspect the equipment's mechanical components, and check the equipment's electrical system for proper function. Additionally, inspect the spiral/helical blades for wear monthly (once per month), lubricate the bearings every three months, and add high-temperature grease. Thoroughly clean the equipment when changing formulations to prevent cross-contamination.