What raw materials can a powdered organic fertilizer production line process? What are the raw material requirements?

It can process organic waste such as livestock and poultry manure, crop straw, mushroom residue, distiller's grains, and food waste. The raw material moisture content must be controlled between 50% and 60% . It must be free of large metal pieces, rocks, and other impurities. Furthermore, the food waste must be free of grease and salt to prevent fermentation from interfering.

Does the fermentation process produce foul odors? How are environmental issues addressed?

The fermentation process produces odors such as ammonia, which require environmental protection equipment. Small production lines can use simple covering or spraying for deodorization; medium- and large-scale production lines require systems such as spray towers and biofilters to absorb and decompose odors. Furthermore, wastewater from equipment cleaning must be collected and treated to avoid direct discharge and ensure compliance with local environmental approval standards.

Is the investment cost significantly different for production lines of different sizes? How long does it take to recoup the investment?

The difference is significant. Equipment investment for a small-scale line is 100,000-300,000 yuan, for a medium-sized line 500,000-1.5 million yuan, and for a large-scale line several million to ten million yuan. The payback period is affected by raw material costs, capacity utilization, and market price. Generally, it takes 1-2 years for a small-scale line and 2-3 years for a medium- to large-scale line.

What is the production cycle for powdered organic fertilizer? How many days does it take from raw materials to finished product?

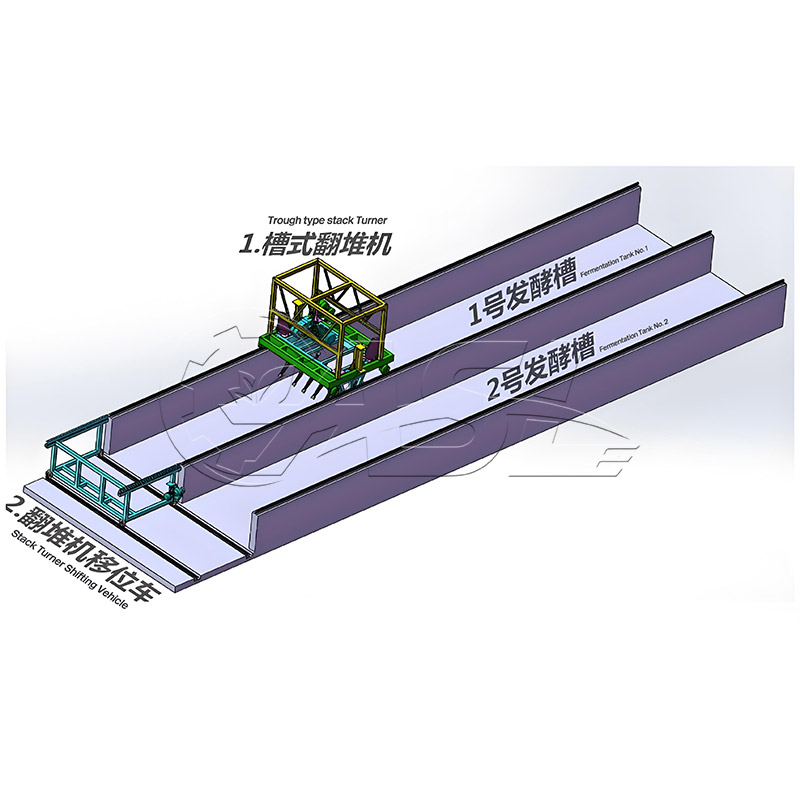

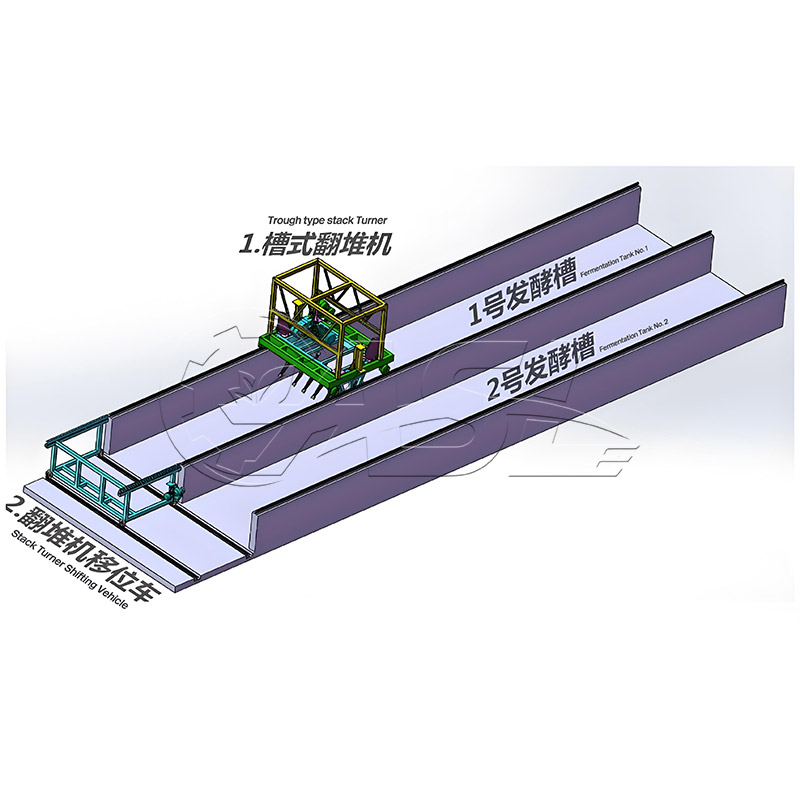

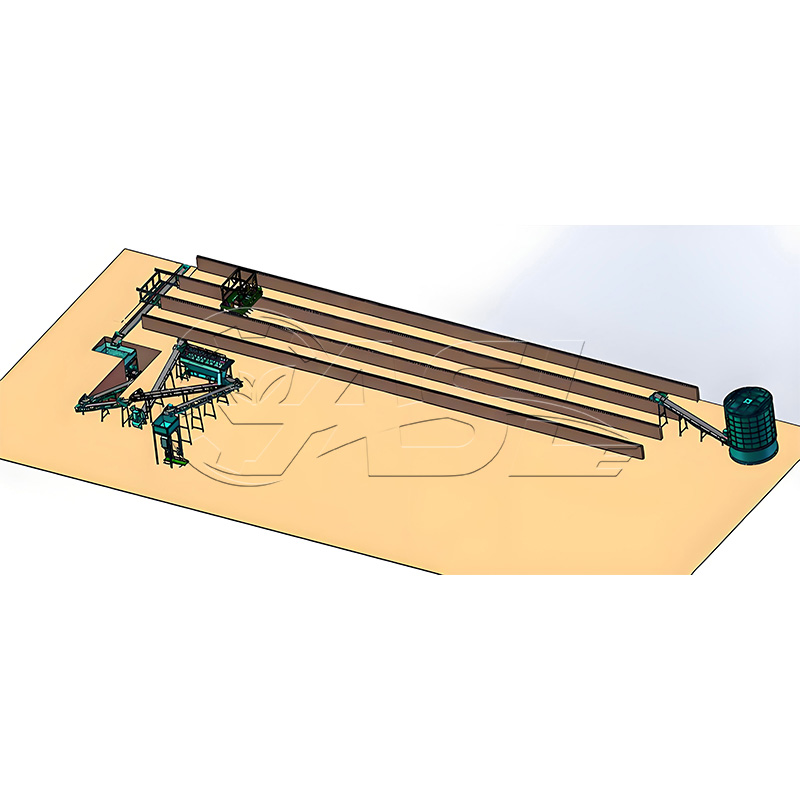

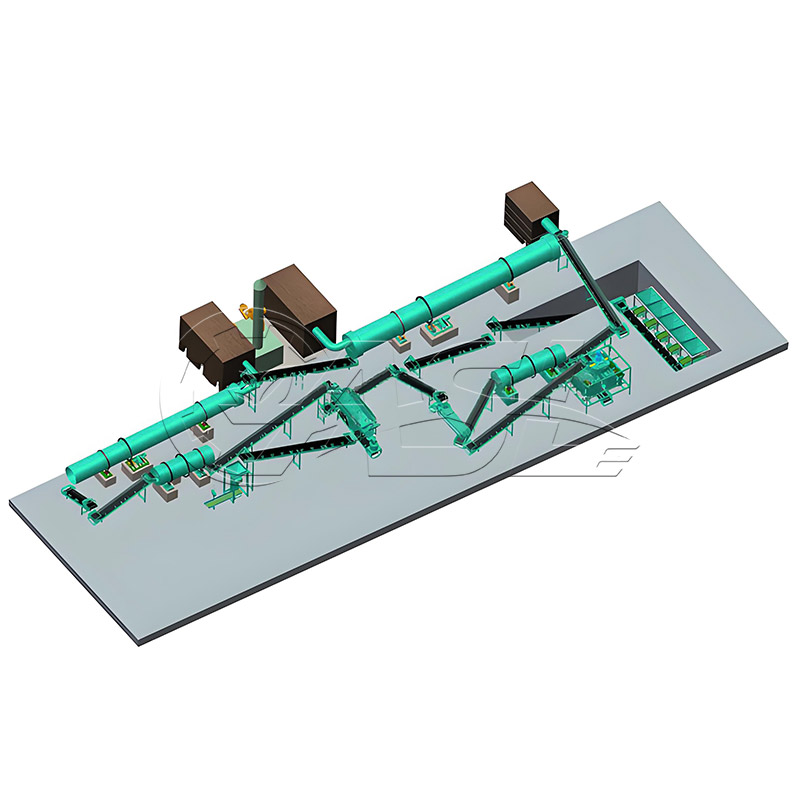

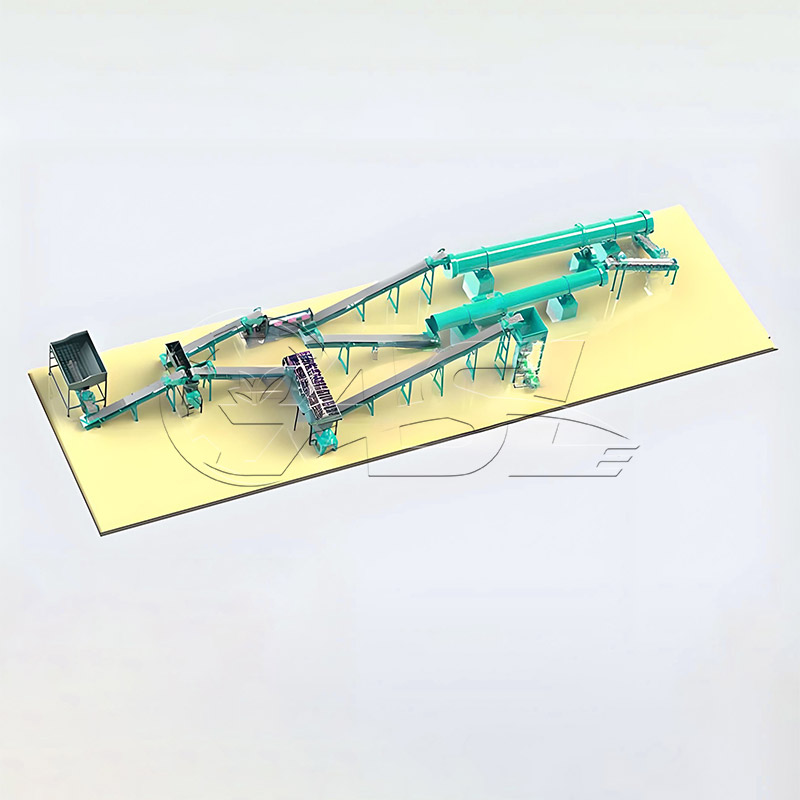

The total cycle is approximately 15-30 days, depending on the fermentation method: windrow fermentation takes 15-20 days, tank fermentation takes 7-10 days, and closed fermentation tanks take 5-7 days. Subsequent processing (drying, crushing, and packaging) takes approximately 1-3 days. Medium- to large-scale production lines have a shorter overall cycle due to their high degree of automation.

What is the storage and shelf life of finished powdered organic fertilizer?

Store in a ventilated, dry place, away from rain, and avoid direct sunlight and moisture. Packaged in moisture-proof woven bags, the unopened product has a shelf life of 6-12 months. Once opened, it should be used as soon as possible, preferably within 1 month.

Can the production line flexibly adjust the product fineness? Can other nutrients be added?

Yes. By changing the pulverizer screen (20-60 mesh), the fineness can be adjusted to meet the needs of different crops . If functional organic fertilizer is to be produced, trace elements, humic acid, probiotics, etc. can be added through the metering and mixing system, and the final product remains in powder form.