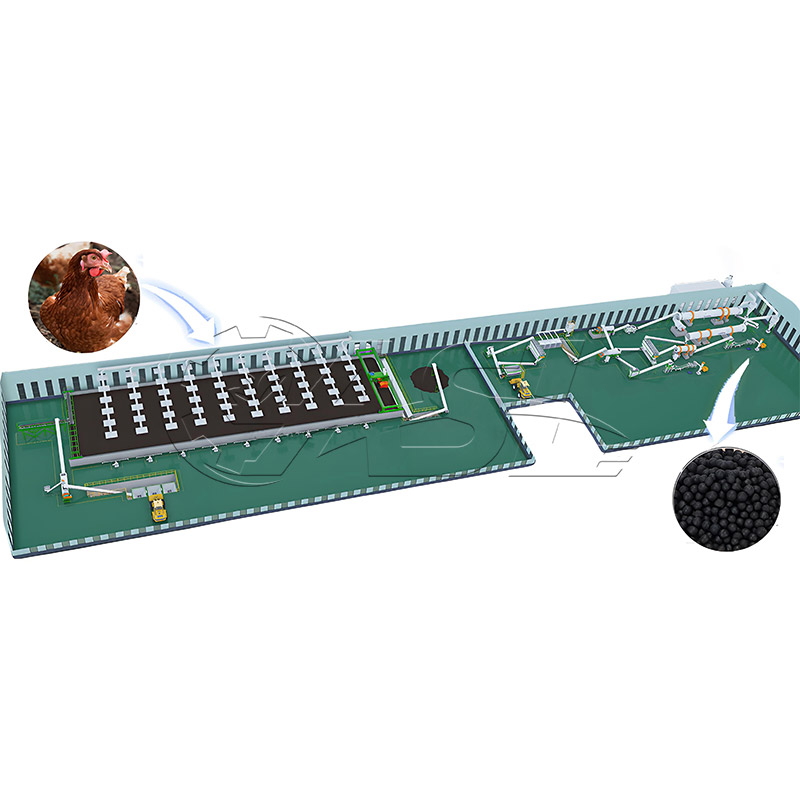

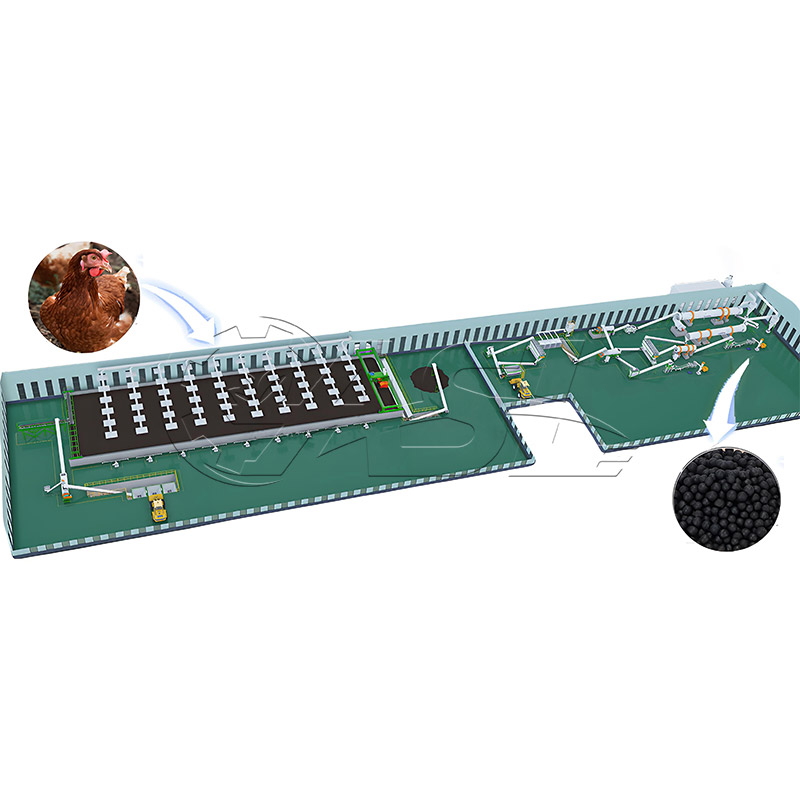

1. Fresh chicken manure has an 80% moisture content. Is it feasible to ferment it directly without solid-liquid separation?

Answer: No. Excessively high moisture content causes the manure to clumping and poor air permeability, leading to a tendency for it to turn black and smelly during anaerobic fermentation, and inability to completely kill insect eggs and pathogens. The moisture content must first be reduced to 50%-60% using a solid-liquid separator, and then adjusted by mixing in auxiliary materials to ensure aerobic fermentation.

2. How much manual labor is required on the production line? Can it be automated?

Answer: A small-scale production line requires 2-3 people (responsible for loading, inspection, and packaging assistance). A medium- to large-scale production line equipped with a PLC electronic control system can achieve "one-button start and stop + fault alarm," requiring only 1-2 people for monitoring and emergency response, eliminating the need for manual intervention in the core processes (conveying, pelletizing, and cooling).

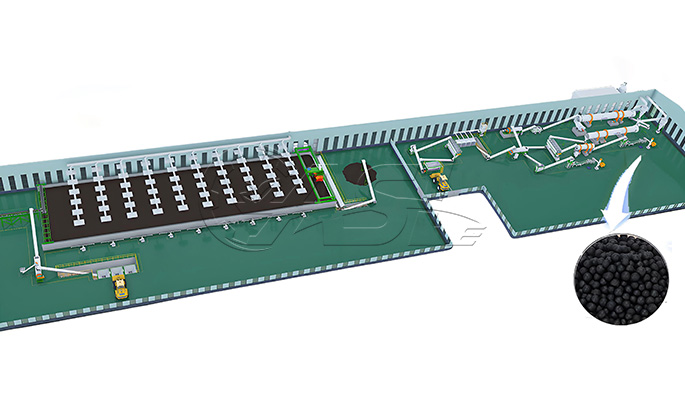

3. Chicken manure contains impurities such as chicken feathers and plastic. Can the production line completely remove these impurities?

Will this affect the quality of the finished product? A: These can be removed through multiple stages without affecting the quality of the finished product:

Pre-treatment: Vibratory/drum screening machines can remove over 80% of impurities such as feathers and stones.

Crushing: A magnetic separator installed at the crusher inlet removes metal impurities and pulverizes the feathers into fine fibers, which can be mixed into organic fertilizer to increase the organic matter content.

If there are a lot of plastic impurities, manual sorting is required before the raw materials are loaded.

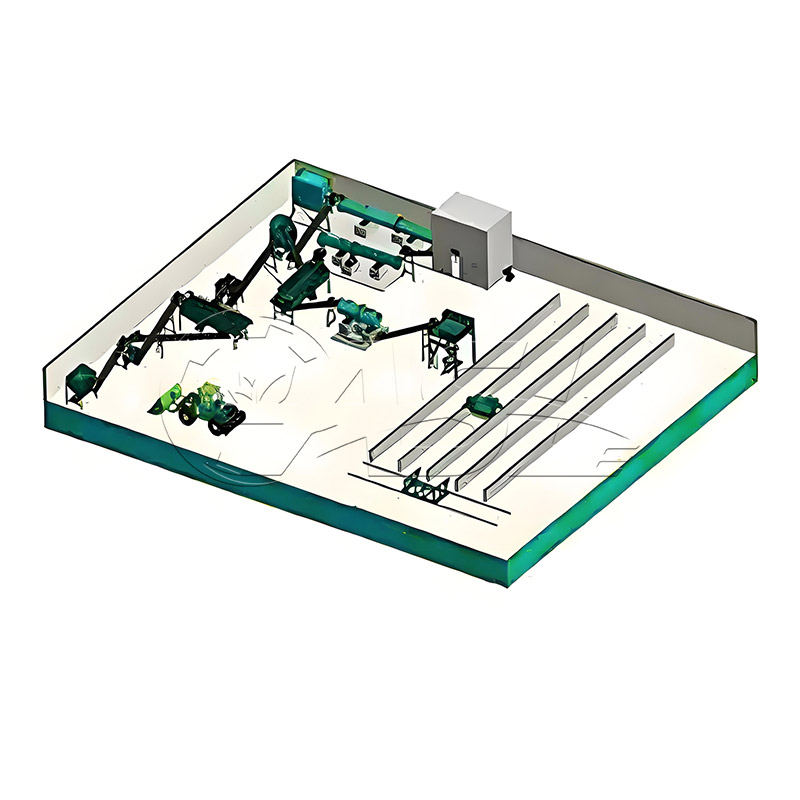

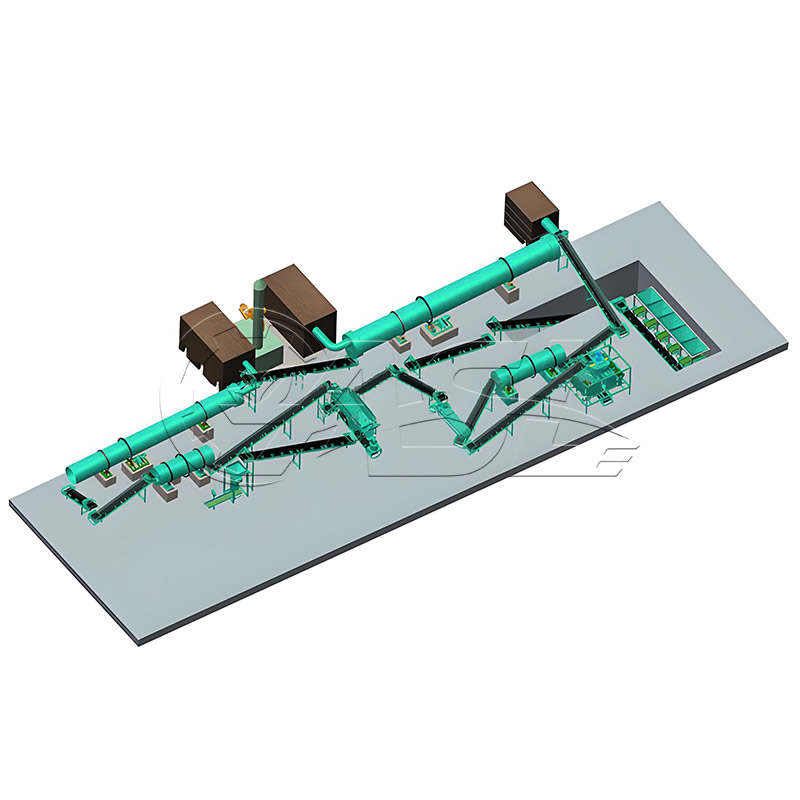

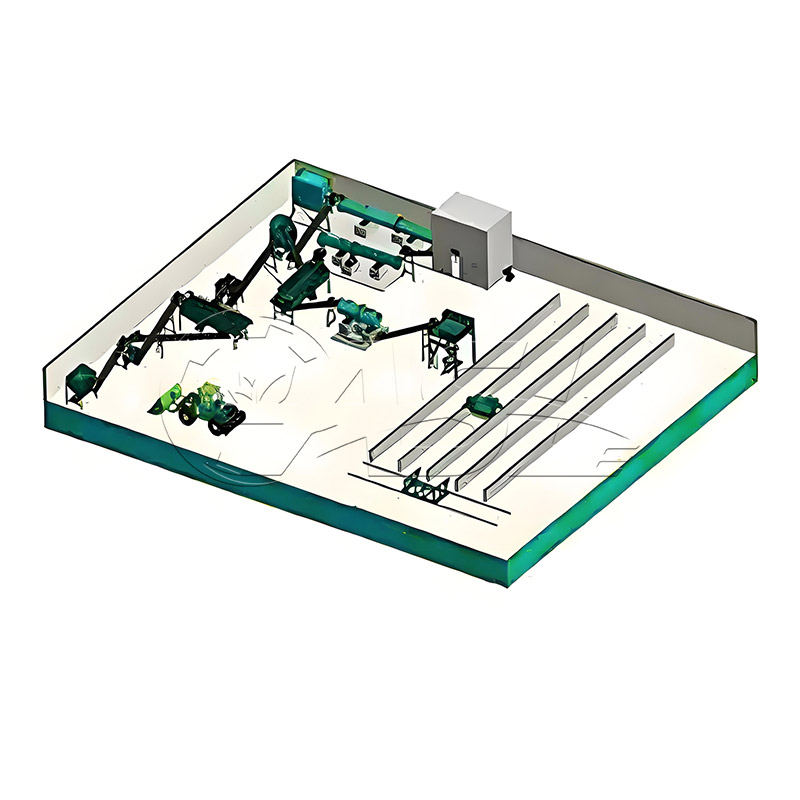

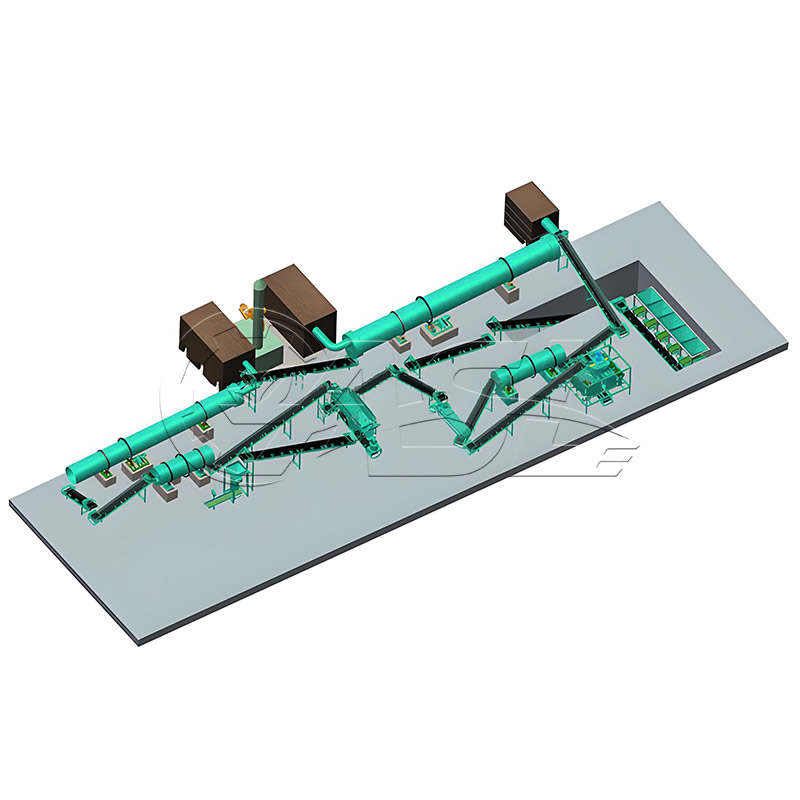

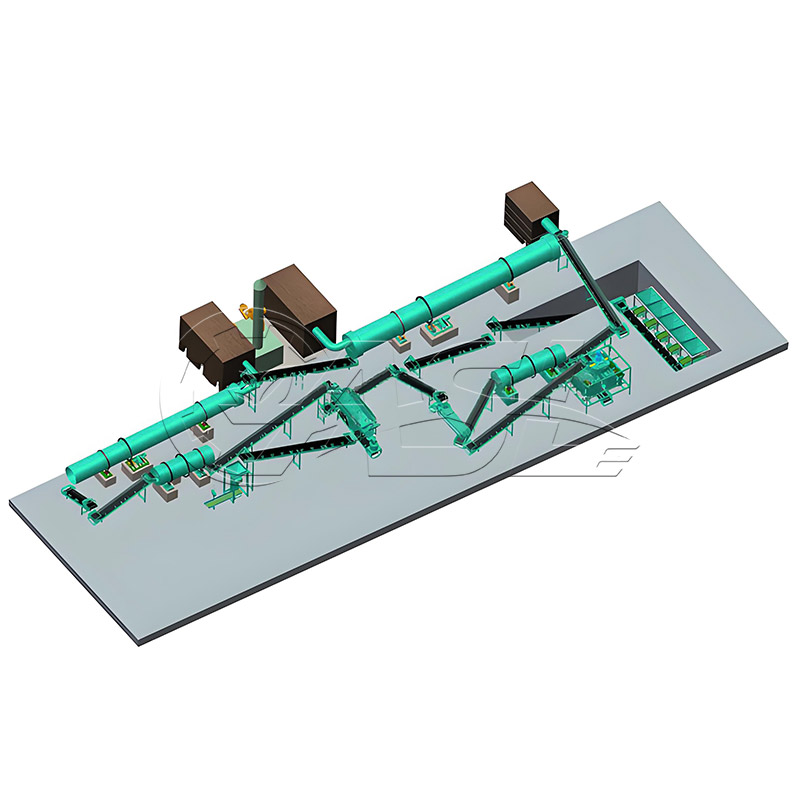

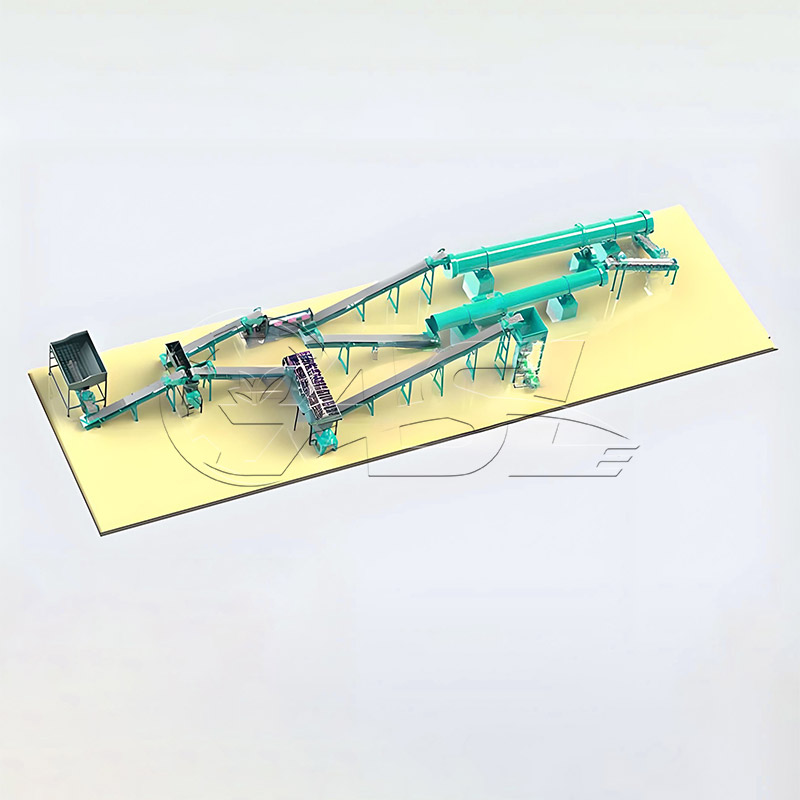

4. What is the required floor space for the production line? What are the site requirements?

The floor space is related to processing capacity: a 5-ton/day production line requires approximately 500-800 square meters (including raw material storage, production, and finished product areas); a 10-20-ton/day production line requires approximately 1,000-1,500 square meters; and a production line of 50 tons/day or more requires over 2,000 square meters. Site requirements: ① Hardened ground (load-bearing capacity ≥ 5 tons/m2, suitable for equipment and raw material storage); ② Proximity to the raw material source (to reduce transportation costs for fresh chicken manure and prevent deterioration); ③ Access to water and electricity (voltage 380V, water pressure ≥ 0.3 MPa); ④ Away from residential areas (≥ 500 meters to minimize odor).

5. Besides chicken manure, can the production line process other livestock and poultry manure? Does it require equipment modification?

Yes, most equipment does not require modification; only process parameters need to be adjusted:

Pig manure: The process is the same as chicken manure. After solid-liquid separation, the fermentation stage can be entered. No adjustment to granulation parameters is required.

Cow manure: No solid-liquid separation is required. Direct screening and mixing with a small amount of chicken manure (to adjust the carbon-nitrogen ratio) can be performed for fermentation. A cage mill should be used for the pulverization stage.

For sheep manure, duck manure, etc., the drying time only needs to be adjusted according to the moisture content; no major equipment modifications are required.