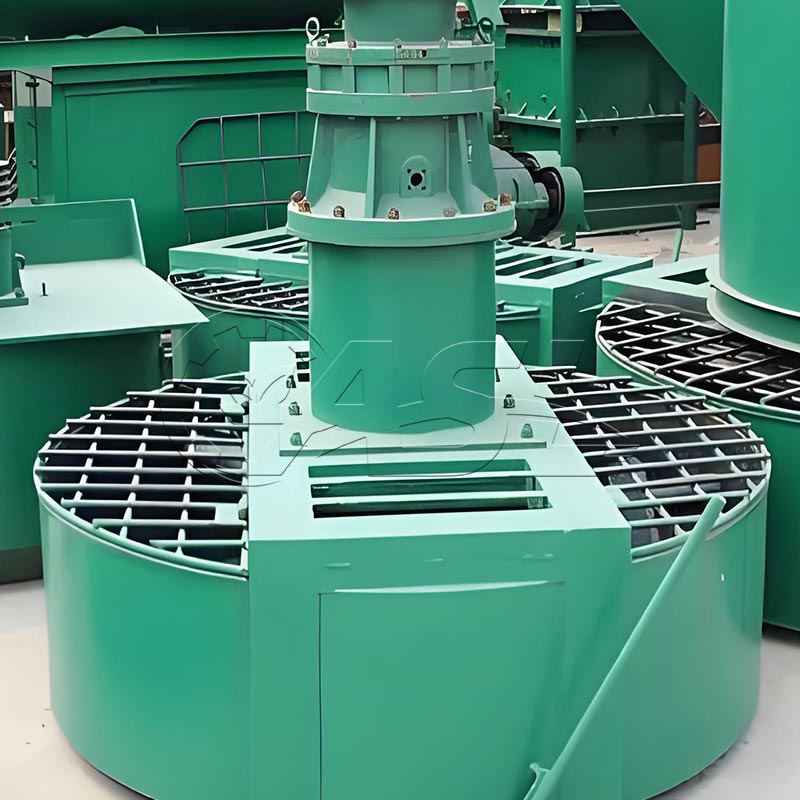

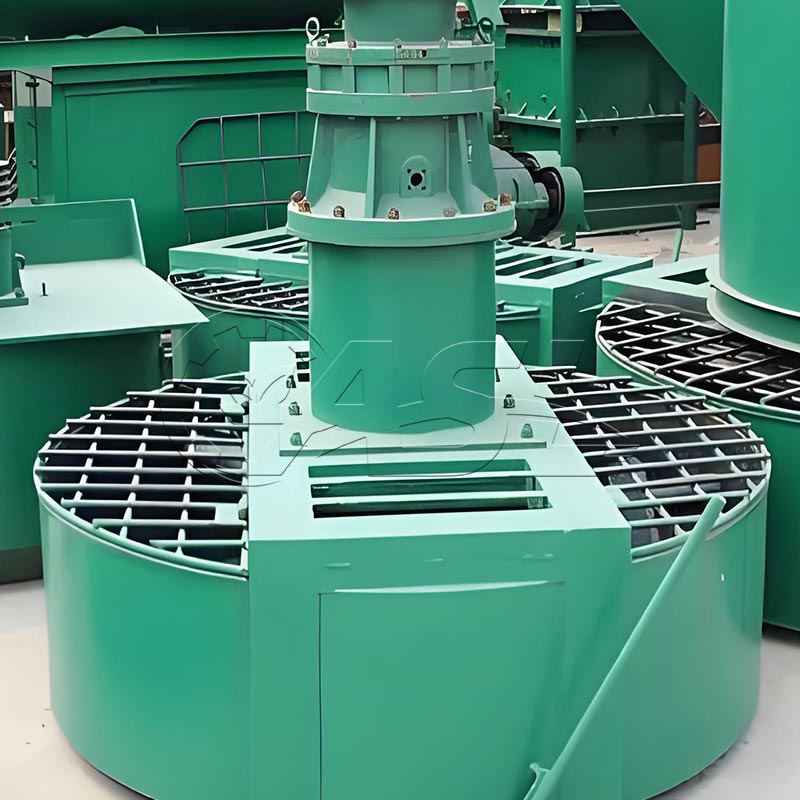

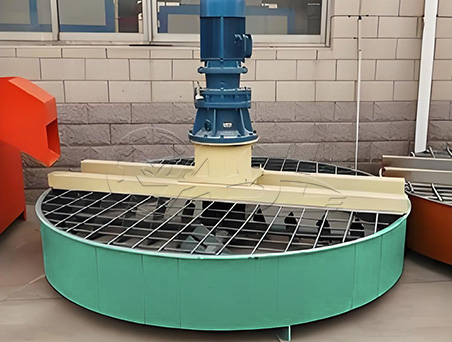

Disc mixer structure:

1. Frame: All working elements of the machine are mounted and fixed to the frame, which is welded from high-quality carbon steel plates and channel steel.

2. Drive Connection: A pinwheel reducer drives the main shaft.

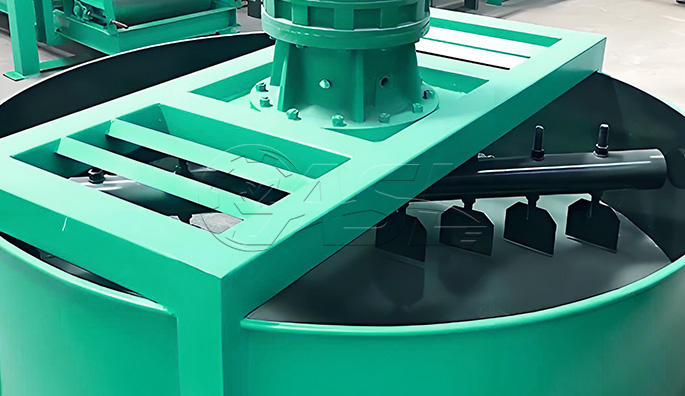

3. Mixing Section: The drive wheel transmits power to the main shaft via a pin coupling. This evenly rotates the material within the mixing chamber, ensuring thorough mixing and significantly reducing residual material.

Working principle of the Disc mixer:

The vertical disc mixer uses the rapid rotation of the screw to lift the raw materials from the bottom of the barrel through the center to the upper part, where they are then scattered in an umbrella-like manner and returned to the bottom. This causes the raw materials to tumble and stir within the barrel, evenly mixing large quantities of raw materials in a short period of time. This machine integrates vertical lifting, a mixing chamber, and horizontal material conveying. It has the advantages of a simple and compact structure, a small one-time investment, economical and practical, easy maintenance, and no need for special production space. It mixes evenly and can produce premixes, concentrates, complete powders, etc.

Advantages of the Disc mixer:

1. High Efficiency:

The mixing blades are made of a highly wear-resistant special alloy, resulting in high mixing efficiency and a compact footprint.

2. Convenient and Easy to Use:

The cycloidal pinwheel reducer provides a compact structure, easy operation, uniform mixing, and convenient unloading and conveying.

3. Rational Structure:

The disc mixer features top feeding and bottom discharge, ensuring a rational structure.

4. Low Noise:

Tight sealing between all joints ensures smooth operation and low noise.

Model | ASLPJ-1600 | ASLPJ-1800 | ASLPJ-2000 | ASLPJ-2200 | ASLPJ-3000 |

Dimensions(mm) | 1600×1600×1800 | 1800×1800×1800 | 2000×2000×1800 | 2200×2200×1850 | 3000×3000×2000 |

Edge Height(mm) | 400 | 400 | 400 | 400 | 400 |

Disc Diameter(mm) | 1600 | 1800 | 2000 | 2200 | 3000 |

Motor Power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 15 |

Reducer Model | BLD15-87 | BLD15-87 | BLD15-87 | BLD15-87 | BLD15-87 |

Mixing Speed(r/min) | 16 | 16 | 16 | 16 | 16 |

Main Plate Thickness(mm) | 5 | 5 | 5 | 5 | 5 |

Floor Plate Thickness(mm) | 8 | 8 | 8 | 8 | 8 |

Mixing Capacity(t/h) | 2-4 | 3-5 | 4-6 | 6-8 | 8-12 |

What organic fertilizer raw materials are suitable for organic fertilizer disc mixers?

They are primarily suitable for processing organic fertilizer raw materials after fermentation or in the pre-processing stage, such as composted livestock and poultry manure, straw powder, mushroom residue, humus, and peat. They are particularly suitable for powdered or granular materials with a moisture content of 10%-20% and no large lumps. Micronutrients and microbial agents can be added to the materials.

Will composted wet materials stick to the mixer? How can this be avoided?

If the moisture content of the material exceeds 20% (slightly sticky), slight sticking may occur. This can be alleviated by: ① Select a model with a wear-resistant rubber scraper, which should adhere closely to the inner surface of the disc to promptly remove sticking materials; ② Reduce the single feed volume to avoid material accumulation; ③ Apply an anti-stick coating to the inner surface of the disc if necessary.

Is the equipment prone to wear? What is the lifespan of core components (such as the scraper and disc)?

When the material contains a high level of sand or coarse fiber, the scraper and disc bottom are prone to wear. The scraper is made of 65Mn wear-resistant steel or rubber and has a lifespan of approximately 3-6 months. The inner wall of the disc can be fitted with a wear-resistant lining, extending its lifespan to 1-2 years. Wear can be replaced individually, reducing maintenance costs.

Will the mixing process destroy the beneficial bacteria in the organic fertilizer?

The disc mixer uses physical mixing, without high temperatures or strong shear forces, and will not damage the activity of the inoculant. However, it is important to note that when mixing materials containing inoculants, avoid operating in high temperatures (>40°C) and limit the mixing time to 5-10 minutes. (Excessive mixing may cause slight temperature increases due to frictional heat.)

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap