What are the processes and characteristics of the granulation process?

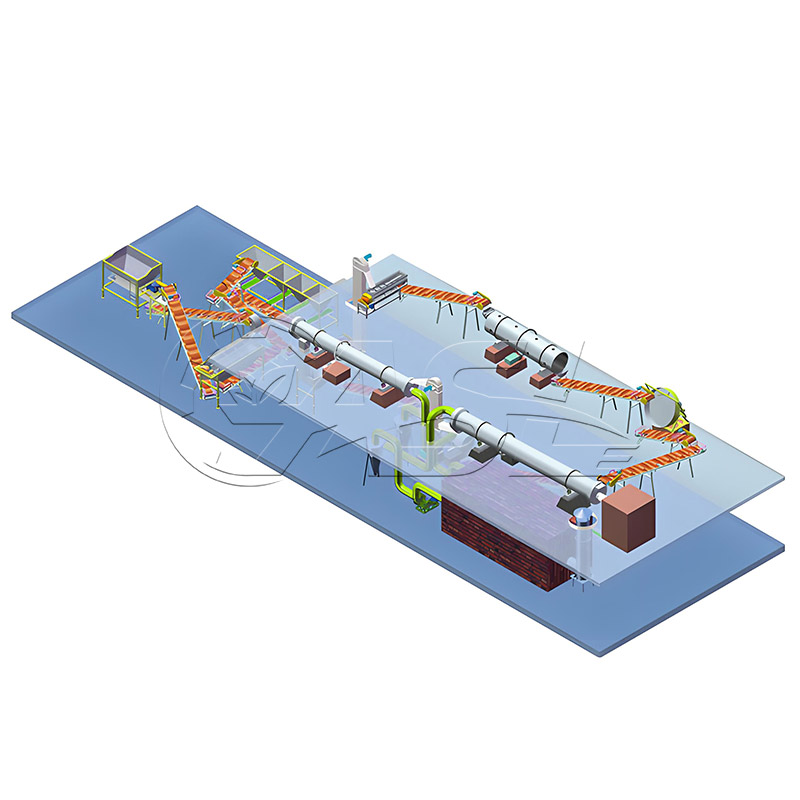

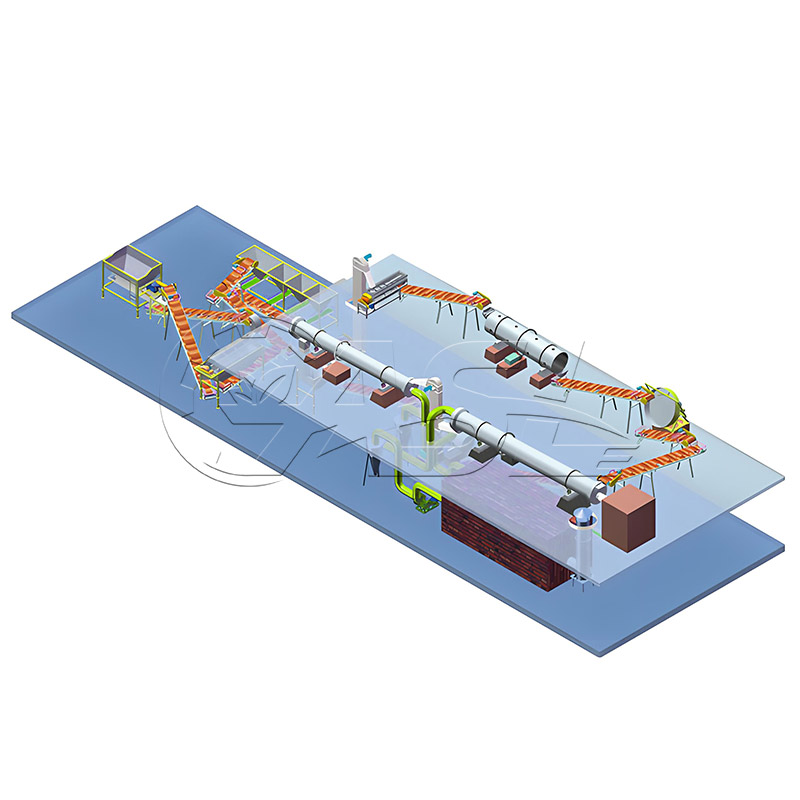

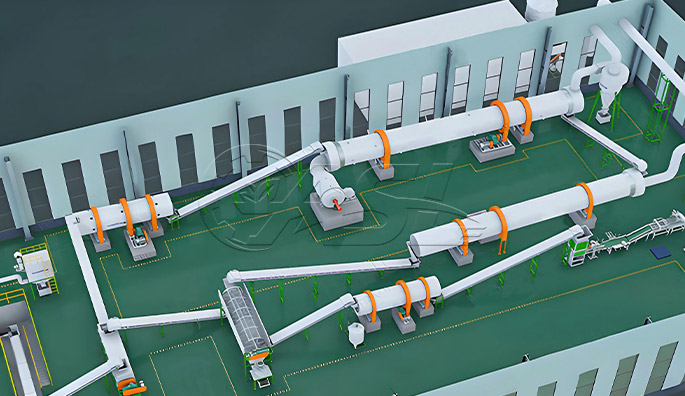

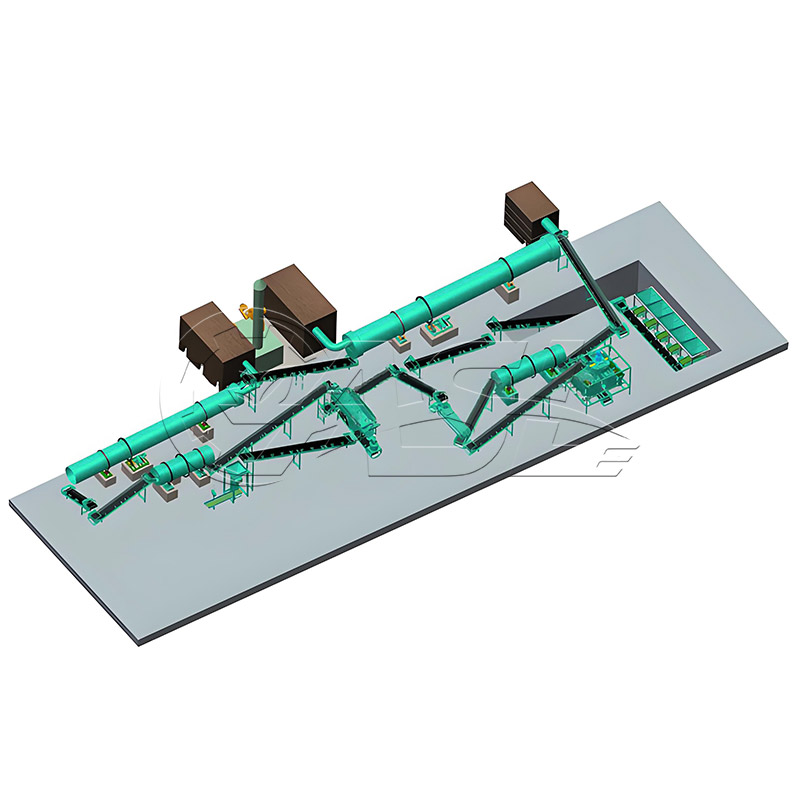

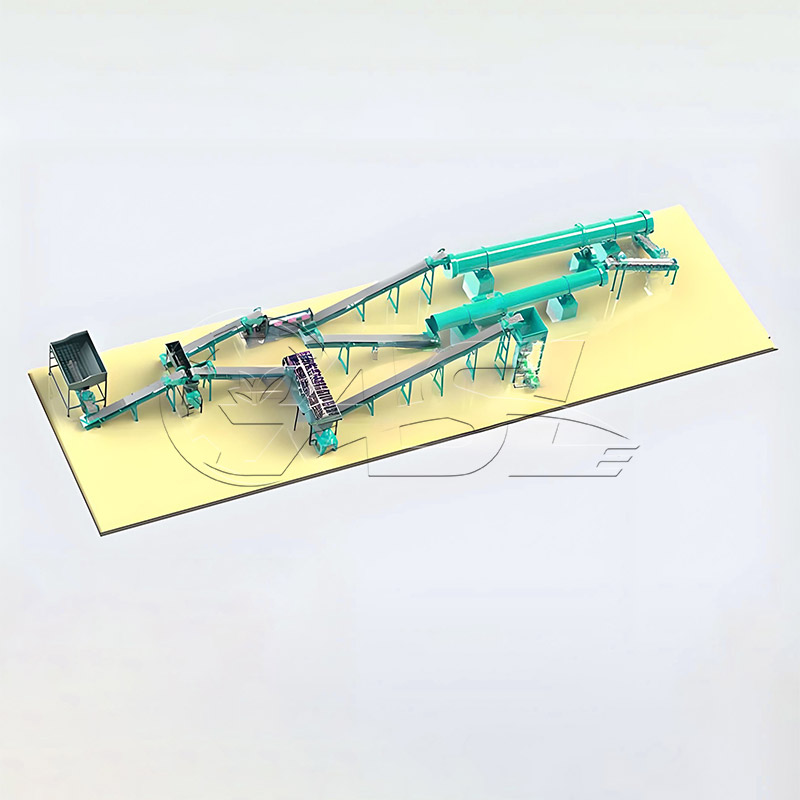

Drum granulation: Suitable for large-scale production, with high granule roundness and strength, but requiring a high equipment investment.

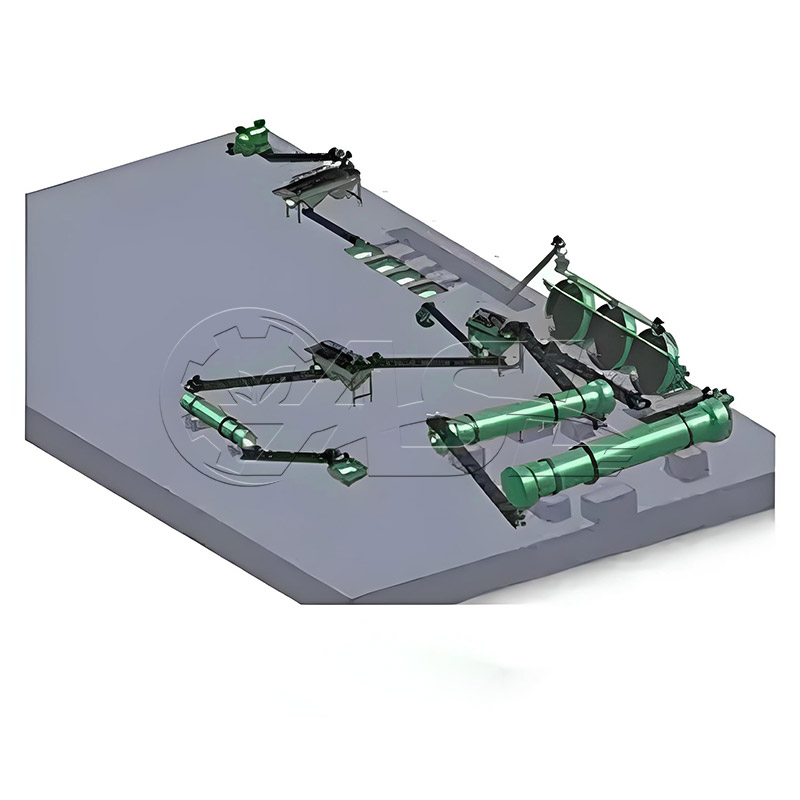

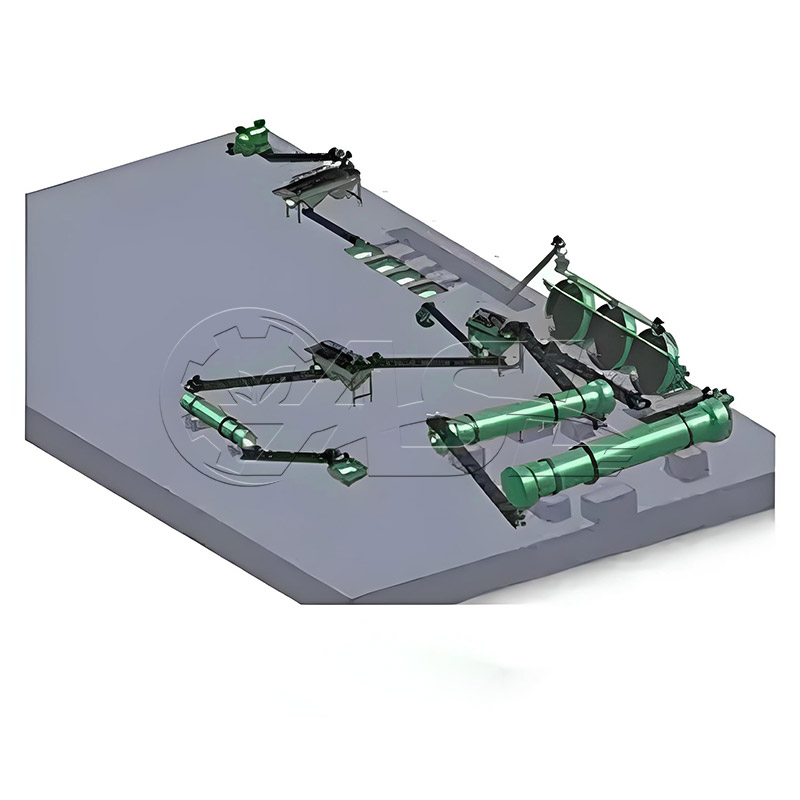

Disc granulation: Simple structure, low energy consumption, suitable for small production lines or frequent formulation adjustments, with limited production capacity.

Extrusion granulation: No water addition is required, making it suitable for sensitive formulations such as those containing high urea. However, the granule appearance is slightly inferior, and maintenance costs are higher.

How can we ensure uniform nutrient content in compound fertilizers?

Raw materials are crushed and screened to 80-100 mesh to ensure uniform particle size. A PLC-controlled automatic batching system accurately controls the amount of material. A high-efficiency mixer ensures a uniformity of over 95%. Regular sampling and calibration parameters are conducted.

What are the raw material requirements for the production line? What are the consequences of unstable raw material quality?

The production line requires raw materials of high purity and low impurities. Raw materials should be of moderate particle size, generally crushed to 80-100 mesh, to facilitate mixing and granulation. Unstable raw material quality can make it difficult to precisely control the formulation, leading to fluctuations in the nutrient content of the product and affecting fertilizer efficiency.

How are the waste gas, wastewater, and waste residue generated during the production process handled?

①Waste gas: Dust is recovered using a pulse dust collector, and hot air furnace exhaust undergoes desulfurization and denitrification treatment.

②Wastewater: Sedimentation, filtration, and biochemical treatment are followed before reuse or discharge.

③Waste residue: Unqualified particles and waste dust can be landfilled, while nutrient-rich residue can be used for soil improvement.