How does a twin-shaft continuous mixer differ from a single-shaft continuous mixer in its operating principle?

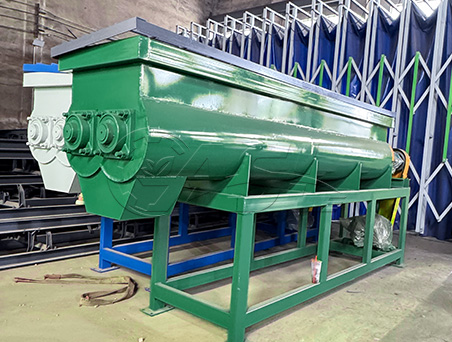

A twin-shaft continuous mixer utilizes two parallel, counter-rotating mixing shafts. Staggered spiral blades or paddles on the shafts propel the material forward while creating intense shear, compression, and convection. The material is repeatedly torn and mixed between the two shafts, significantly improving uniformity. Single-shaft mixers, on the other hand, rely primarily on the propulsion and tumbling of the single shaft's spiral to achieve mixing, resulting in weaker shear forces. This difference results in shorter mixing times and higher uniformity, making twin-shaft mixers suitable for production scenarios requiring stringent mixing quality.

Are twin-shaft continuous mixers prone to material entanglement or blockage? How can this be prevented?

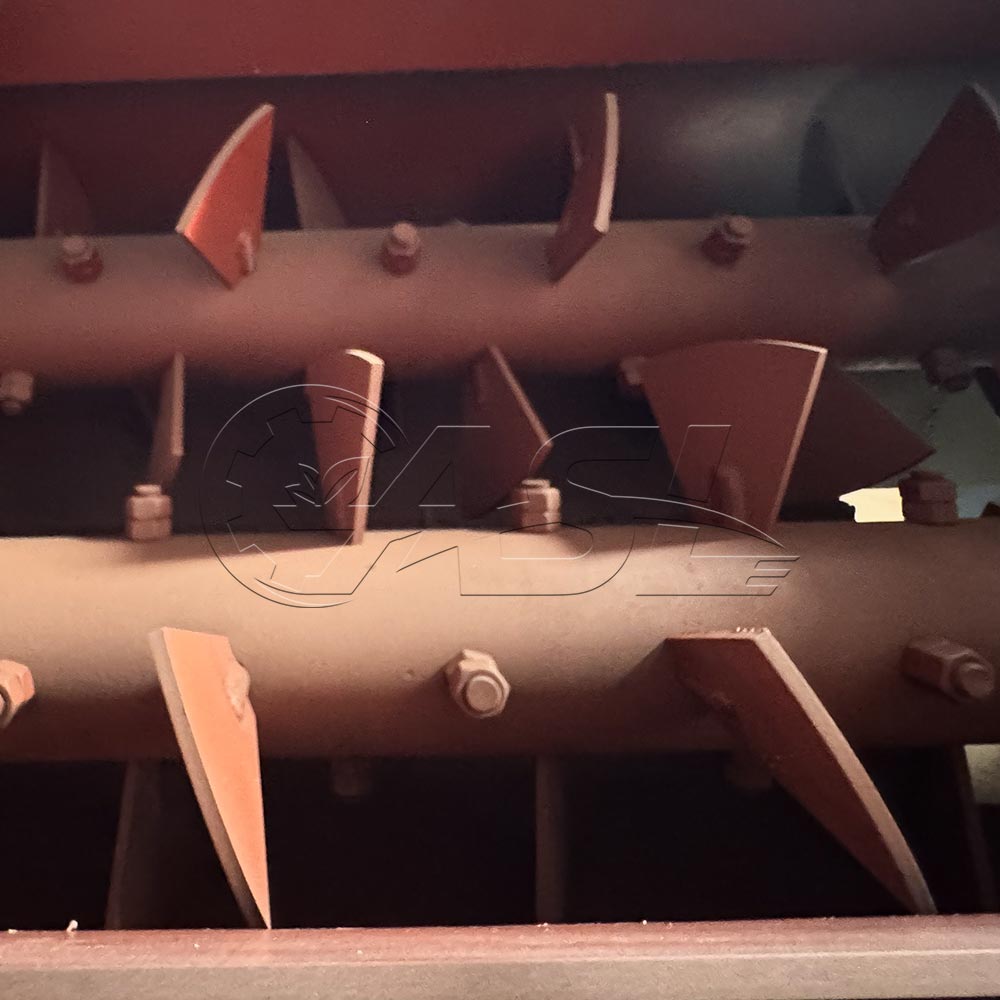

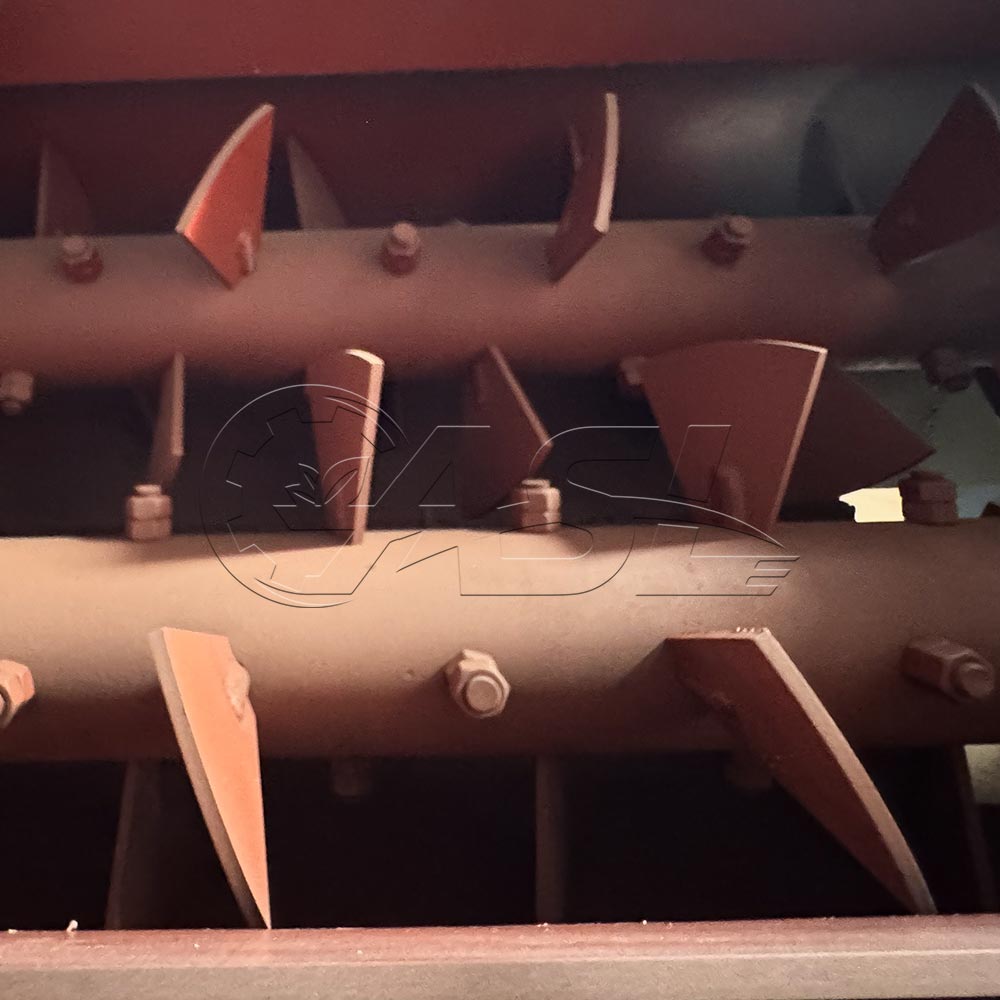

Compared to single-shaft mixers, twin-shaft continuous mixers have a lower risk of material entanglement due to the shear forces generated by the counter-rotating shafts. However, this risk can still occur when handling materials containing long fibers. Preventative measures: ① Ensure that fibrous materials such as straw are shredded to less than 5cm in length before feeding; ② Select a machine with "anti-entanglement blades" (the blades have serrated edges to cut fibers); ③ Control the feed rate to avoid overloading. If a blockage occurs, use the machine's built-in "reverse function" (available on some models) to reverse the material flow and then remove any entangled material.

What are the key points of daily maintenance for a twin-shaft continuous mixer?

Daily maintenance needs attention: ① Bearing lubrication: Fill the shaft end bearings with lithium-based grease every 8 hours of operation to ensure adequate lubrication; ② Blade inspection: Check the blade fixing bolts weekly to prevent loosening and remove any residual material from the blades; ③ Seals: Check the shaft end seals (mostly a combination of mechanical seals and oil seals) monthly. Replace any leaks promptly; ④ Drive system: Regularly check the reducer oil level and belt tightness (a deflection of 10-15mm is ideal) to prevent transmission failure. A comprehensive overhaul and replacement of aging components is recommended every six months.

How are the dust and odor generated during the operation of a twin-shaft horizontal mixer handled?

To address dust, the equipment can be equipped with a top dust removal port for connection to a bag filter or cyclone separator, achieving dust removal efficiencies exceeding 90%. The feed inlet features a sealed design to minimize dust escape. To address odor, an exhaust gas collection duct can be installed at the top of the mixing drum to direct odorous gases into a biofilter or activated carbon adsorption unit for treatment before discharge. Some models also feature a spray system on the drum wall that uses atomized water to suppress dust and absorb some odors, making it suitable for production environments with stringent environmental requirements.